MLD

MLD

PresentationRELIABILITY AND FLEXIBILITY, COMPATIBLE AT LAST

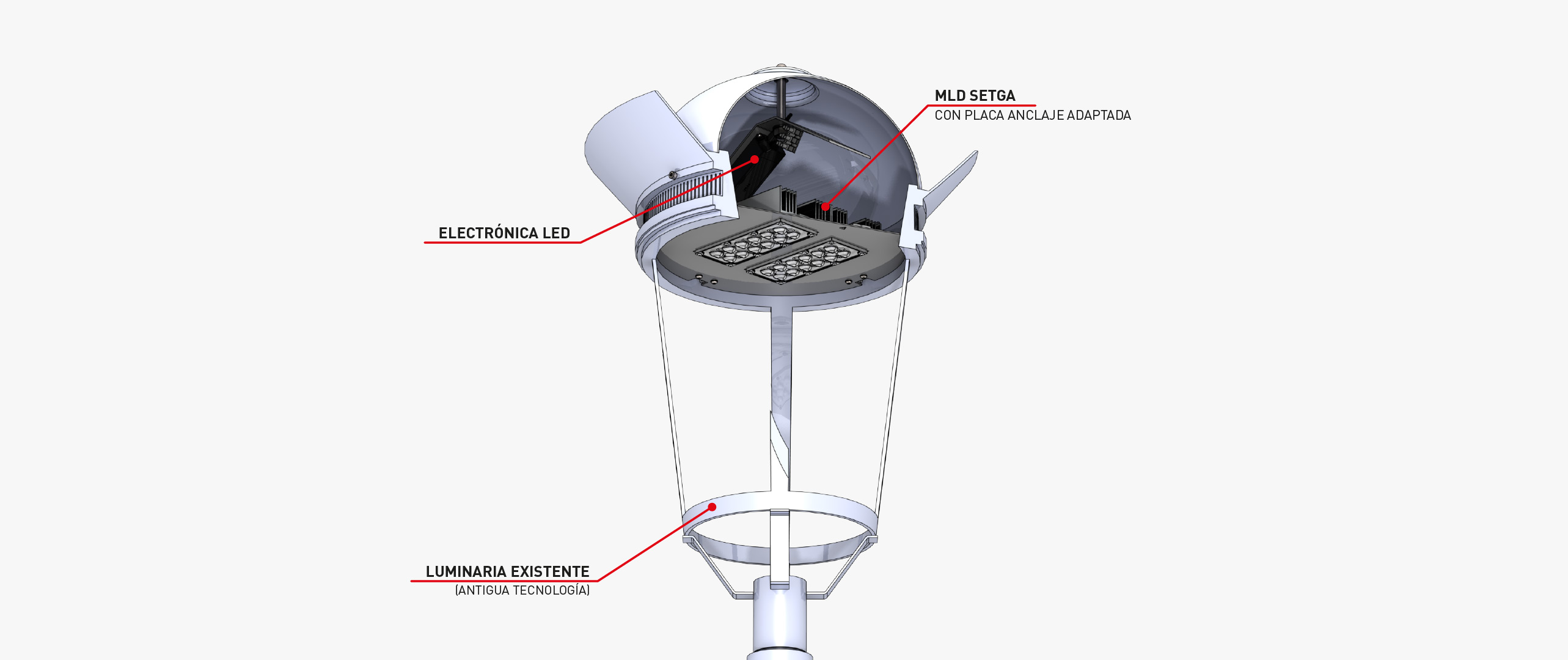

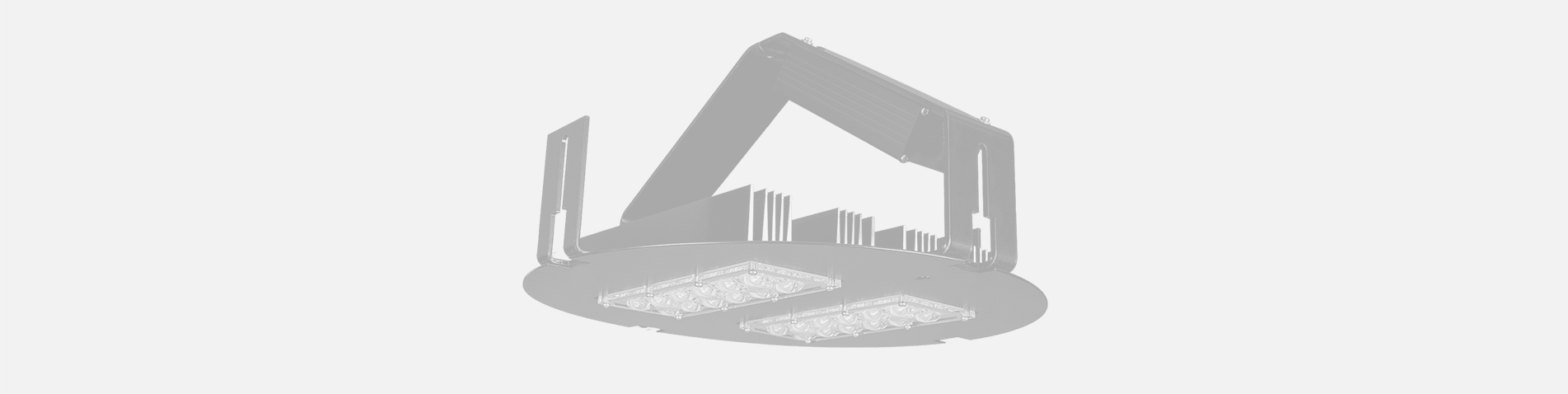

In the MLD module, SETGA has merged the technological reliability of its most advanced LED luminaires with the mechanical flexibility of all its production processes, generating a retrofit alternative adaptable to any pre-existing conventional luminaire model.

ORIGIN AND EVOLUTION

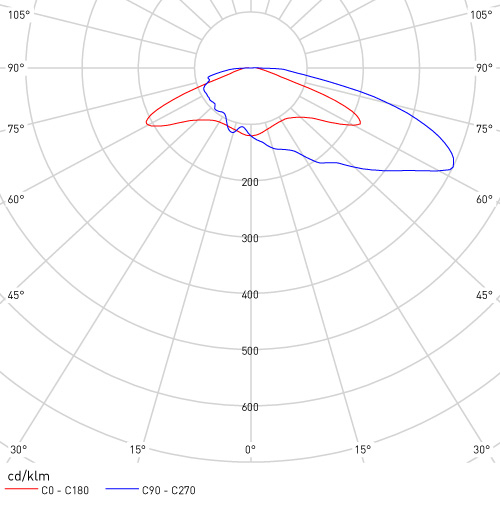

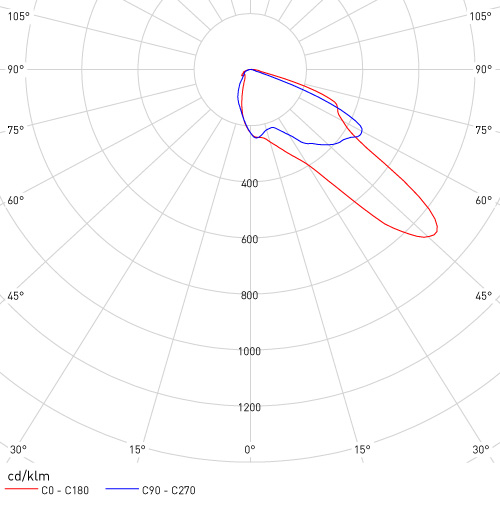

The modular design concept inherent to the MLD series allows for flexible large- or small-scale industrialization.

By using anodized aluminium AL-5754 in the manufacturing process of the lower aluminium frame, the shape can be adapted to the individual needs of each project, an impossible challenge for standard aluminium injection frames.

Finally, the MLD module can be shifted both vertically and horizontally in ornamental lamps, optimizing photometric levels in highly complex lighting designs.

MATERIALS AND STRUCTURE

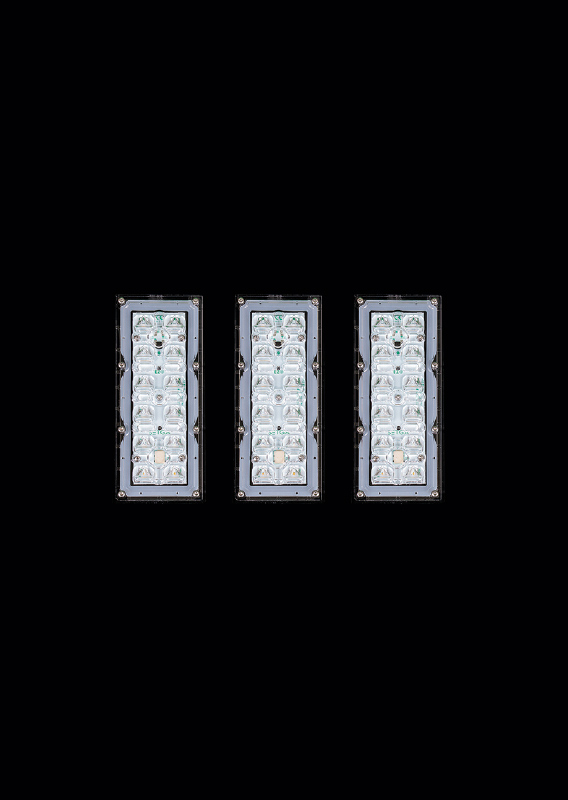

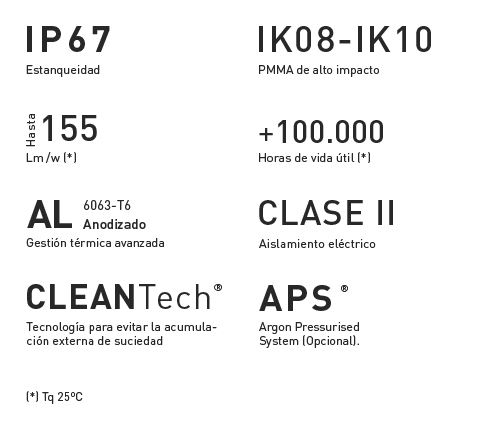

The MLD module is formed by a machined aluminium and anodized body, acting as a direct heat dissipation mechanism and structural element, noted for its high resistance to corrosive environments.

A direct optical closure made of high impact PMMA, due to its high resistance to UV solar radiation, is applied to the lower surface of the module.

Finally, the unit is certified with class II electrical insulation and a watertightness rating of IP67.

SUSTAINABLE DESIGN

Each new MLD is the result of a highly sustainable industrial process, distinguished by its recycling capacity and optimization of applied materials. When compared to other processed aluminium, aluminium AL-5754 and 6063-T6’s high purity ensures full reuse by other industries in future. Additionally, the high thermal conductivity of this material allows for component size adjustment, resulting in advanced thermal performance with lower material density than bodies manufactured from other aluminium.

Technical keys

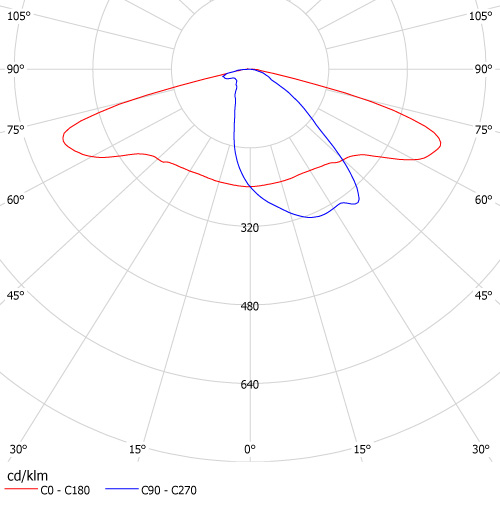

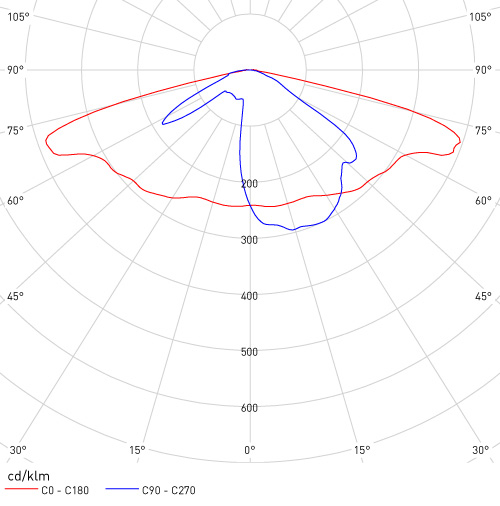

The MLD lamp is based on the principle of direct thermal dissipation between the LED PCB and the compact aluminium chassis. The dissipation body comprises a continuous heat pipe of anodized aluminium 6063-T6, which achieves thermal conductivity levels of 200 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection. The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

Descriptive views

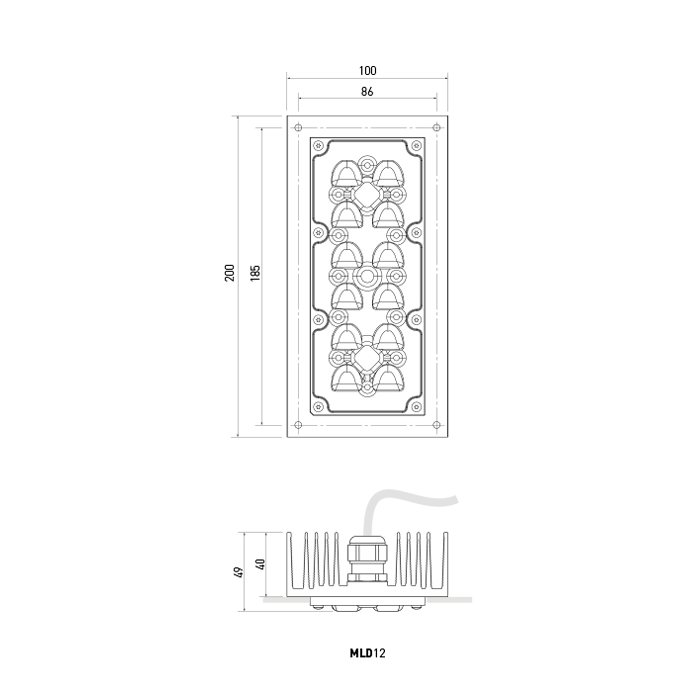

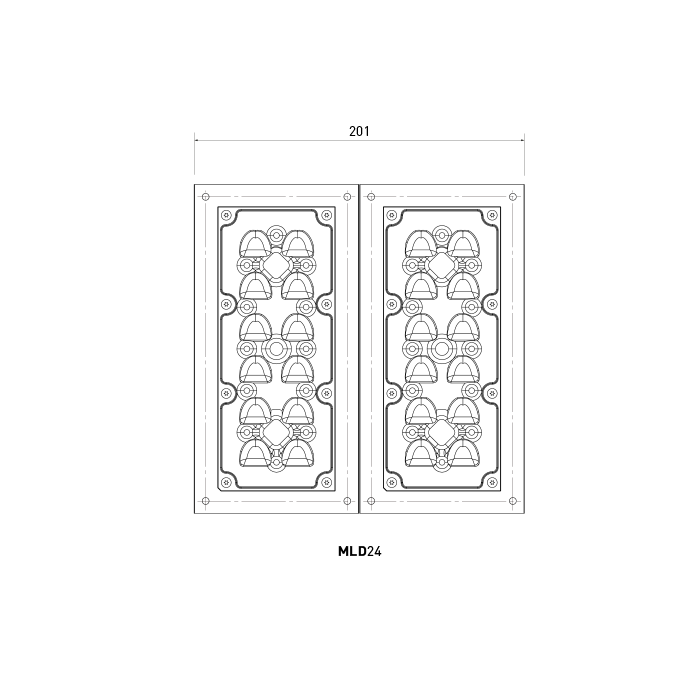

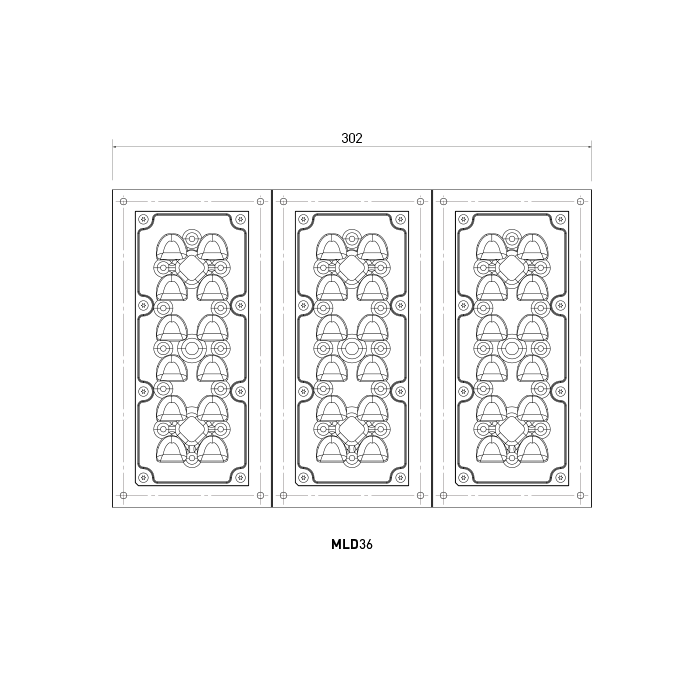

Dimensions and installation

The MLD series is born as a new modular concept with great mechanical flexibility that allows you to upgrade LED lamp lanterns.

The MLD is composed of an aluminum heatsink and a PCB with its corresponding lenses. This assembly is integrated into a special frame for each luminaire, making it a very versatile product.

The MLD is made up of 12 LEDs but its simple coupling allows sets of 12, 24, 36 to be created, as far as necessary.

Compatible

Do you have a technical question?

Ask us