LINED

LINED

PresentationELEMENTAL FREEDOM

Form, in its most elemental state, is capable of feeding the conceptual freedom of any urban evolution process, by integrating simplicity, slenderness and timelessness in every detail. This is why the Lined series has the ability to transform geometric synthesis into the embryo of infinite realities.

ORIGIN AND EVOLUTION

The Lined Series champions the continuity of the design philosophy that inspired the birth of the Tablet series. Once again the simplicity of the Bauhaus design school merges with the timelessness of the current Die gute Form, taking the architectural diversity of the Atlantic urban space and its atmospheric aggressiveness as a starting point.

Since its first pilots in 2010, the Lined series has experienced multiple integration formulas. After more than 30,000 hours of technological evolution, today this state-of-the-art LED series is an icon, illuminating the environs of the 2015 Arnhem Central Station, the Netherlands most avant-garde train station.

MATERIALS AND STRUCTURE

The upper body of the Lined luminaire consists of a machined and anodized aluminium chassis, which serves as a direct mechanism for heat dissipation, as well as a structural element known for high corrosion resistance. The underside of the luminaire is characterized by the application of a tempered glass cover onto which a city logo can be vitrified. Both upper and lower elements are encased in an anodized aluminium AL6063-T5 frame.

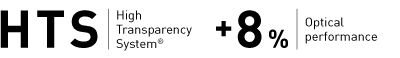

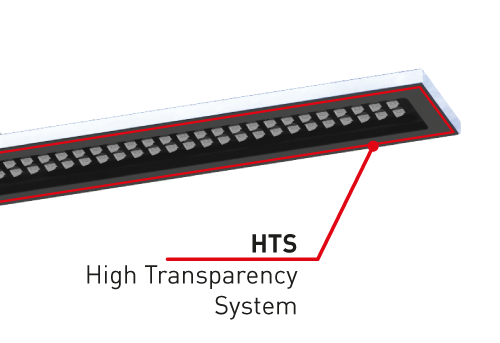

The development of an optical system with HTS® technology has led to an 8% increase in ultimate luminaire efficacy, reducing reflection losses by 55%, compared to market standards that apply a secondary lens system covered with a tempered glass closure.

SUSTAINABLE DESIGN

The design strategy of the Lined series is characterized by the combination of highly sustainable materials. Compared to injected aluminium, high purity aluminium Al 5754 facilitates reuse by other industries in the future. The 100% glass natural origin makes this material fully recyclable and minimizes the environmental impact of its transformation process.

The support of the first European glass processing line powered by solar technology has substantially reduced the carbon footprint of this series. Finally, after the latest revision of the ISO 14001, and implementation of a sustainability master plan, SETGA has driven the design of a long-term recycling system for each component in the Lined series.

Technical keys

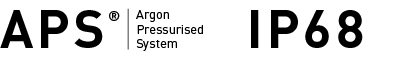

With the Argon Pressurised System (APS)® Lined series’ optical and electronic components are encapsulated in a pressurised atmosphere of argon gas. A watertightness level of IP68 is ensured, making the system resistant to complete and continuous immersion far beyond the requirements of any regulation.

The inert atmosphere in the optical-electronic module guards against condensation, moisture and salinity intrusion, thereby preventing an accelerated ageing process of the system’s sensitive components.

This protective shield is essential in areas where air salinity is a critical lifetime factor for any optical and electronic component.

The ability of this system to preserve the lifetime, efficacy and chromatic quality of the luminaire reduces Up toal Cost of Ownership (TOC) and maintains high demanding visual comfort standards.

The Lined luminaire is based on the principle of direct thermal dissipation between the LED PCB, the compact aluminium chassis and the exterior. The luminaire body comprises a continuous heat pipe of anodized aluminium AL-5754, which achieves thermal conductivity levels of 160 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection.

The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

The redefined composition of the optical system delivers a 55% reduction in reflection levels, a significant drop when compared with market standards that apply a secondary lens scheme and a tempered glass cover. HTS technology enables optical performance levels similar to those obtained with a direct lens system, increasing the overall efficacy of the luminaire (lm/W) by 8%.

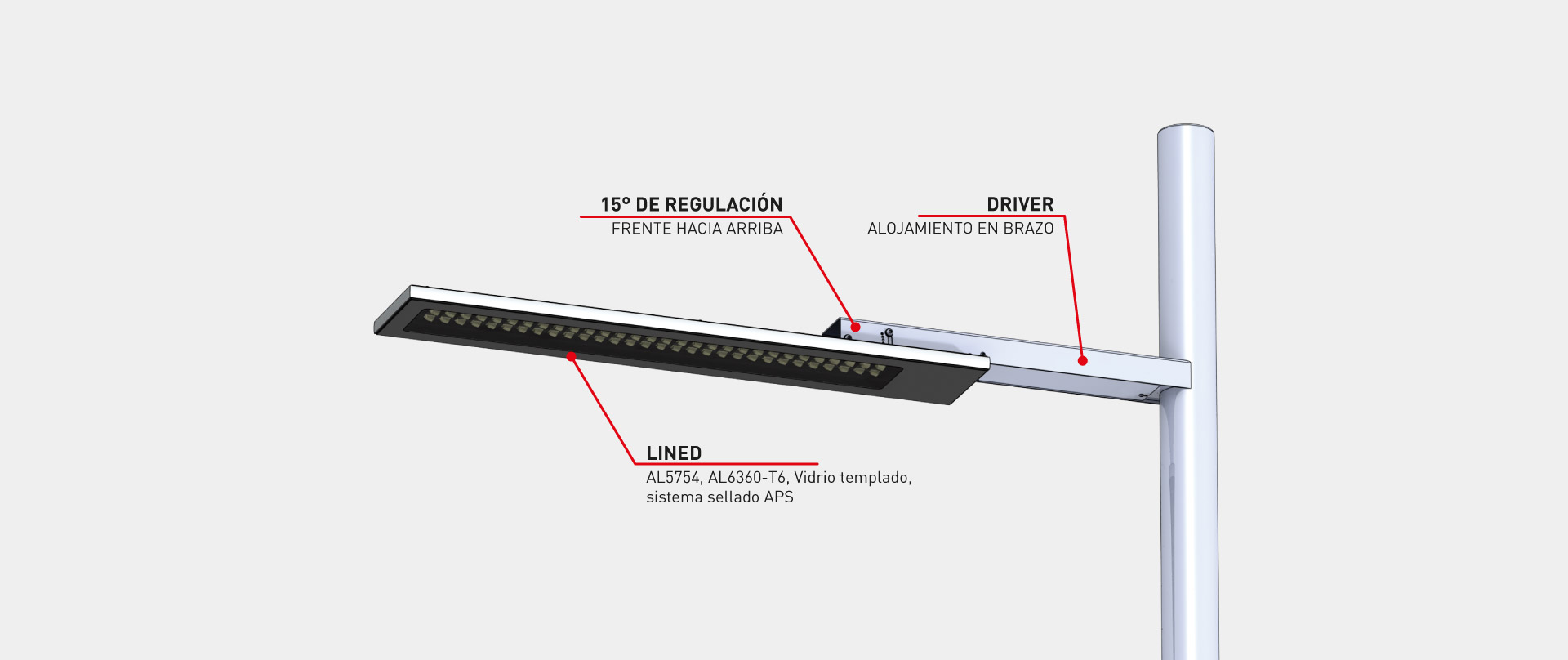

Descriptive views

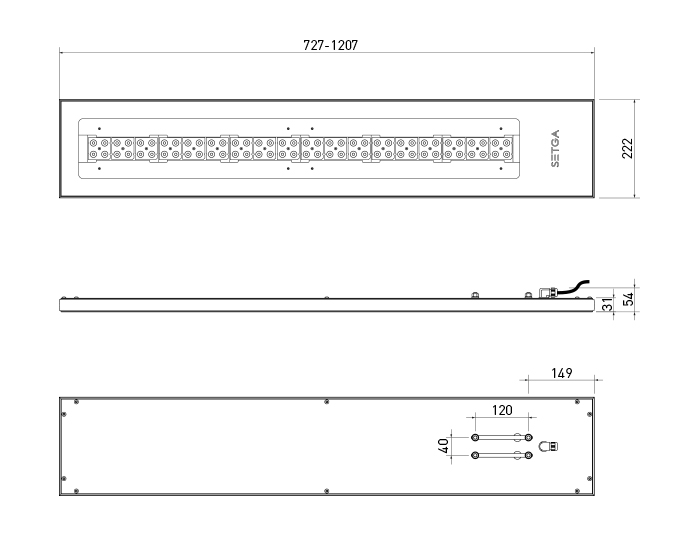

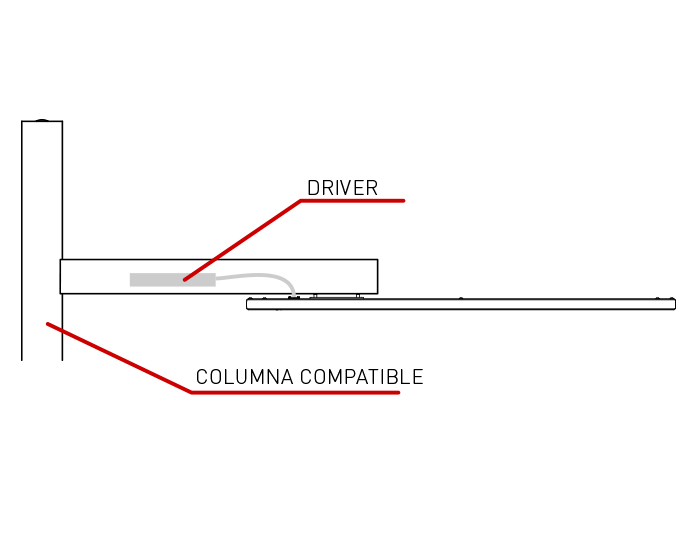

Dimensions and installation

The ultra-compact design of the Lined luminaire achieves a unique visual effect with a thickness of only 31mm. Its length varies depending on the number of LEDs.

The anchor system with 4 bolts is designed to facilitate anchoring to plates allowing some clearance in the position of the anchor holes.

The design is also optimized to fit perfectly with our range of columns so that the bracket fuses perfectly with the Lined. The most used bracket to anchor the Lined to our poles allows a regulation of pitch of 15 ° to upward facing.

Iconic projects

ARNHEM CENTRAAL STATION

Arnhem (Países Bajos)

Do you have a technical question?

Ask us