INFINITUM

INFINITUM

PresentationBALANCE AND LIGHTNESS

Specific urban areas are defined by characteristic architectural perspectives and frames of reference. This is the reason why the Infinitum series releases space from unnecessary poles, providing flow and visual lightness to the environment. The proportionality of the whole and its photometric versatility enables the creation of multiple lighting scenes.

ORIGIN AND EVOLUTION

Conjugating elementary forms generates a harmonic aesthetic language, providing an alternative to the visual imbalance produced by projectors arranged in geometrically dissimilar columns.

During the design process of the Infinitum series, the continuity of the cylindrical shape determined a new conceptual horizon, triggering an ideal symbiosis between column and projectors. Together with its avant-garde lines, this projector is characterized by its functionality and adaptability. Each projector can be shifted 360 degrees both vertically and horizontally, integrating a highly versatile LED module capable of generating both accent scenes through concentrated optics, as well as directional distributions through extensive optical systems.

MATERIALS AND STRUCTURE

The cylindrical body of the projector Infinitum is made of a main AISI304 or AISI316 stainless steel structure, polished and painted, whose aim is to avoid the corrosive action of highly aggressive environments such as coastal areas. In turn, the series integrates an internal extruded and anodized 6063-T6 chassis, which acts as a continuous thermal dissipation conduit. Depending on the specific needs of each project, it is possible to vary the length and width of the Infinitum projector, adapting it to new applications.

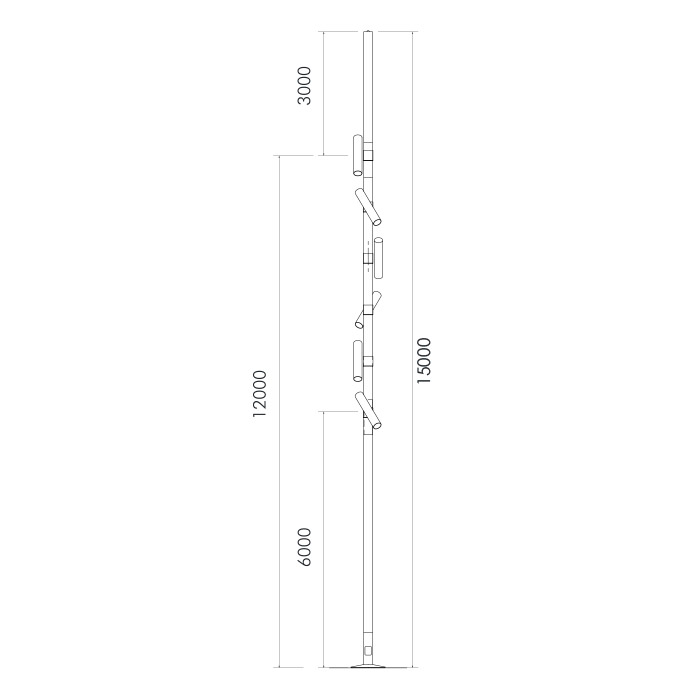

Finally, the Infinitum column and its adjustable fastening systems are available in stainless steel AISI304 or AISI316, either painted or polished, reaching a standard height of 15 m.

SUSTAINABLE DESIGN

The Infinitum projector incorporates one of the most recycled materials in the world: steel. Its planned reintroduction in the productive cycle of other industries once the luminaire’s useful life ends will mean significant energy savings compared to the use of other metals.

Likewise, and unlike materials such as aluminum injection, the application of extruded aluminum in the manufacture of the dissipating chassis allows its reuse in other product categories.

Following the implementation of ISO 14001, and the development of the sustainability master plan, SETGA has promoted the reduction of the carbon footprint in all its components as well as the design of a long-term recycling system for each component.

Technical keys

The Infinitum projector is based on the principle of direct thermal dissipation between the LED PCB and the compact aluminium chassis. The dissipation body comprises a continuous heat pipe of anodized aluminium 6063-T6, which achieves thermal conductivity levels of 200 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection.

The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

According to the US Energy Agency, relief on the upper surface of the fixture severely hinders the dissipation process that takes place by convection, becoming a critical element for performance and life.

To overcome this challenge and to enhance the natural self-cleaning process, SETGA has equipped the Infinitum projector with a completely uniform cylindrical surface, thus preventing dirt accumulation, and the ensuing obstruction and inefficiency of the thermal dissipation system.

Descriptive views

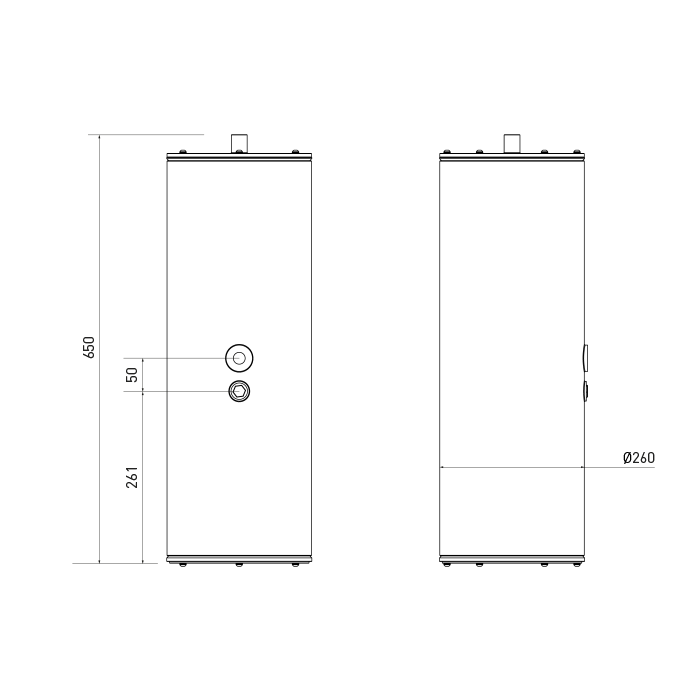

Dimensions

Here are the basic dimensions of the INFINITUM series:

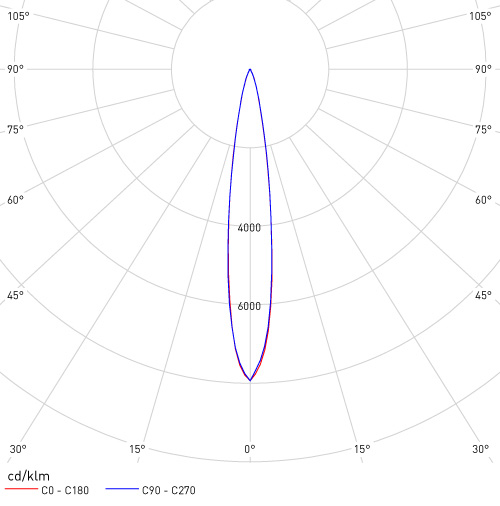

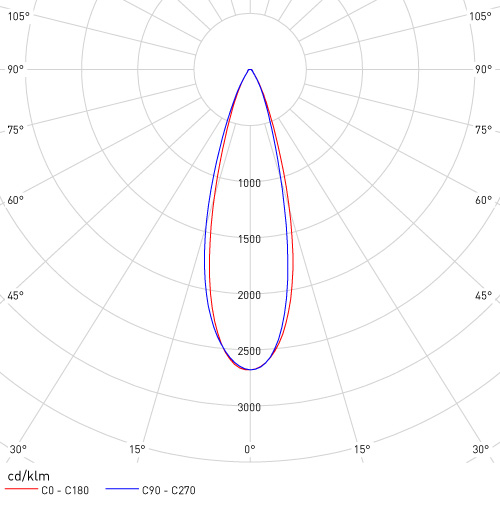

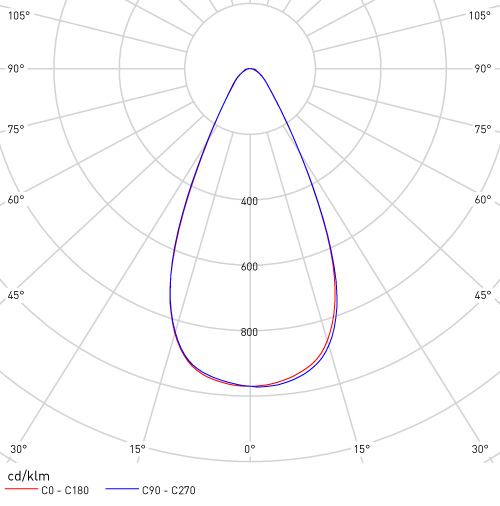

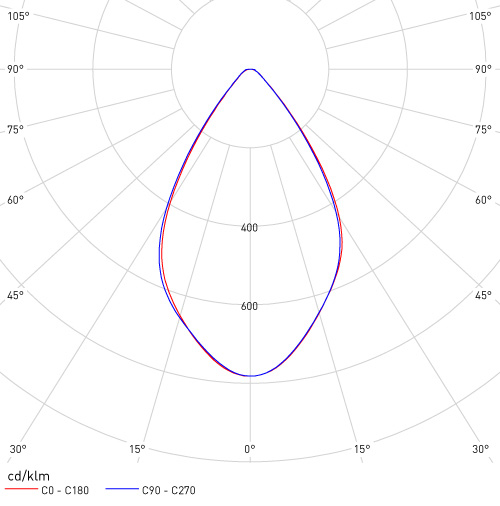

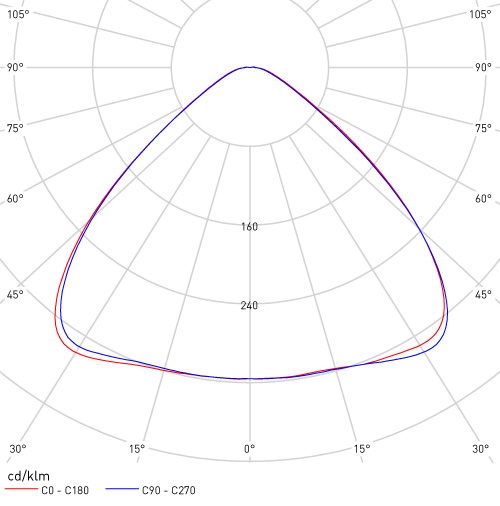

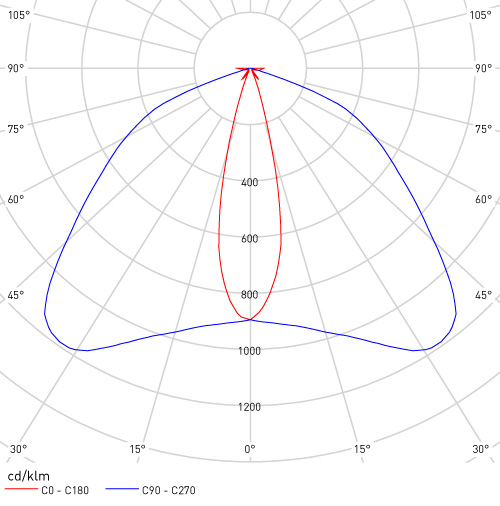

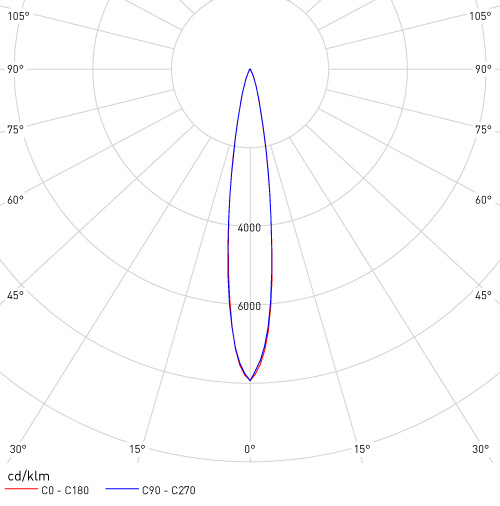

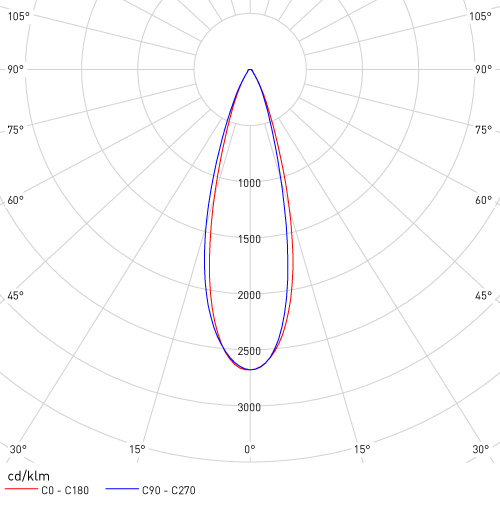

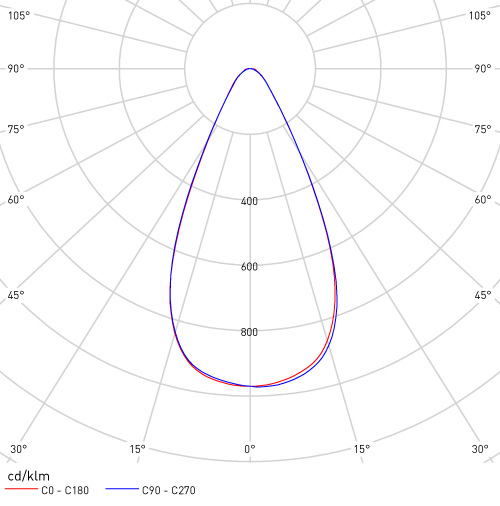

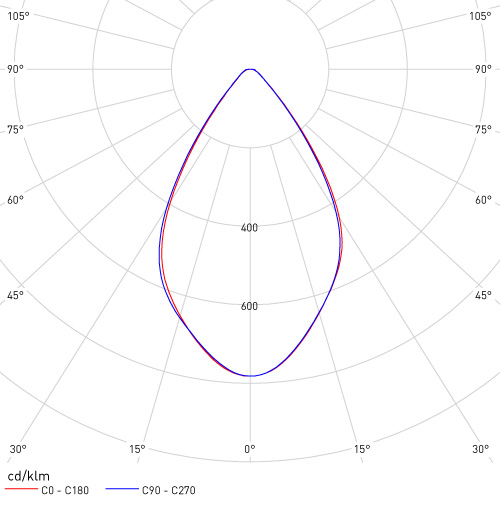

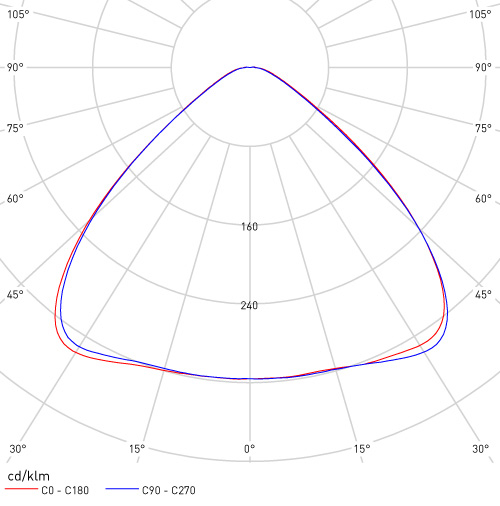

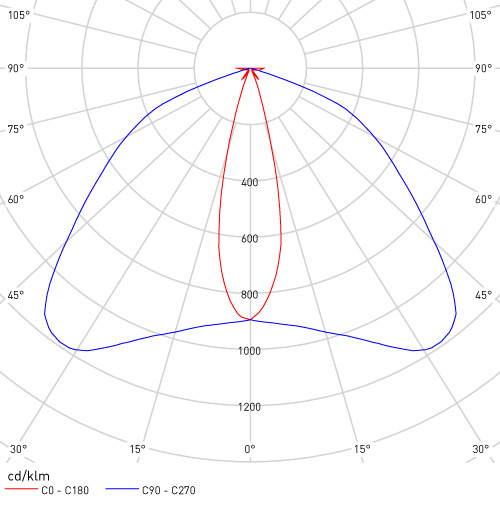

Photometry

Standard Photometries. The SETGA optical department can study additional configurations adapted to each project.

Creators

Jesús Fole

Architect and Product Designer (Pontevedra)

Do you have a technical question?

Ask us