HL

HL

PresentationURBAN INDIVIDUALITY

Noble materials are expressed through their encounter with light. The challenge of the HL projector is to facilitate and adapt them to the characteristics of each urban space. For this purpose, this series introduces a linear geometry that can be integrated into any constructive element.

ORIGIN AND EVOLUTION

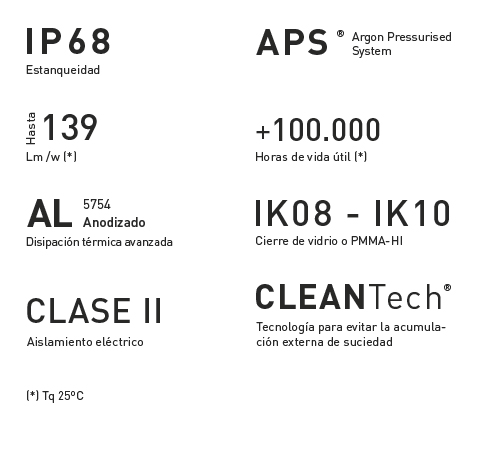

Since the first edition of the HL series in 2009, the performance of its electronic and optical components has undergone a rapid evolution, while its technology argon gas APS® – IP68 has remained unchanged, proving its effectiveness in critical applications submitted to the impact of rain, moisture and salinity.

The HL series has been designed to be incorporated into ground applications orientated at light monuments or to generate accent scenes, as well as side applications features that are characteristic in walkways, bridges and roads, thus ensuring high levels of uniformity. Its multi-configurable optical system make this series adaptable to any lighting concept, responding precisely to the photometric requirements of any technical lighting project.

MATERIALS AND STRUCTURE

The underside of the HL projector consists of a machined and anodized aluminium Al 5754 chassis, which serves as a direct mechanism for heat dissipation, as well as a structural element known for high corrosion resistance. The upper body HL projector is characterized by the application of a tempered glass cover onto which a city logo can be vitrified. Both upper and lower elements are encased in an anodized aluminium AL6063-T6 frame or AL6063-T6.

The development of an optical system with HTS® technology has led to an 8% increase in ultimate luminaire efficacy, reducing reflection losses by 55%, compared to market standards that apply a secondary lens system covered with a tempered glass closure.

SUSTAINABLE DESIGN

The design strategy of the HL series is characterized by the combination of highly sustainable materials.

Compared to injected aluminium, high purity aluminium Al 5754 facilitates reuse by other industries in the future. The 100% glass natural origin makes this material fully recyclable and minimizes the environmental impact of its transformation process.

With the support of the first European glass processing line powered by solar technology, the carbon footprint of this series has been substantially reduced. Finally, after the latest revision of the ISO 14001, and implementation of a sustainability master plan, SETGA has driven the design of a long-term recycling system for each component in the HL series.

Technical keys

With the Argon Pressurised System (APS)® HL series’ optical and electronic components are encapsulated in a pressurised atmosphere of argon gas. A watertightness level of IP68 is ensured, making the system resistant to complete and continuous immersion far beyond the requirements of any regulation.

The inert atmosphere in the optical-electronic module guards against condensation, moisture and salinity intrusion, thereby preventing an accelerated ageing process of the system’s sensitive components. This protective shield is essential in areas where air salinity is a critical lifetime factor for any optical and electronic component. The ability of this system to preserve the lifetime, efficacy and chromatic quality of the luminaire reduces Total Cost of Ownership (TOC) and maintains high demanding visual comfort standards.

The HL projector is based on the principle of direct thermal dissipation between the LED PCB, the compact aluminium chassis and the exterior. The luminaire body comprises a continuous heat pipe of anodized aluminium AL-5754, which achieves thermal conductivity levels of 160 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection. The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

The redefined composition of the optical system delivers a 55% reduction in reflection levels, a significant drop when compared with market standards that apply a secondary lens scheme and a tempered glass cover. HTS technology enables optical performance levels similar to those obtained with a direct lens system, increasing the overall efficacy of the luminaire (lm/W) by 8%.

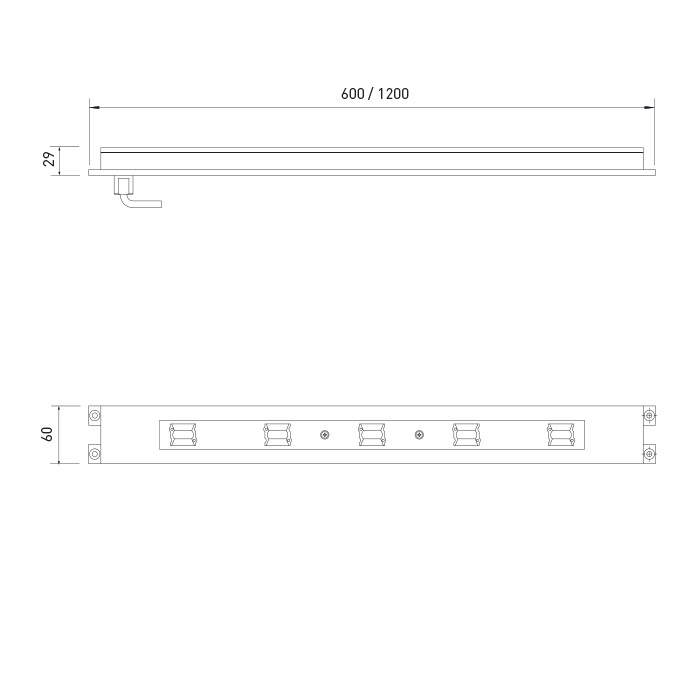

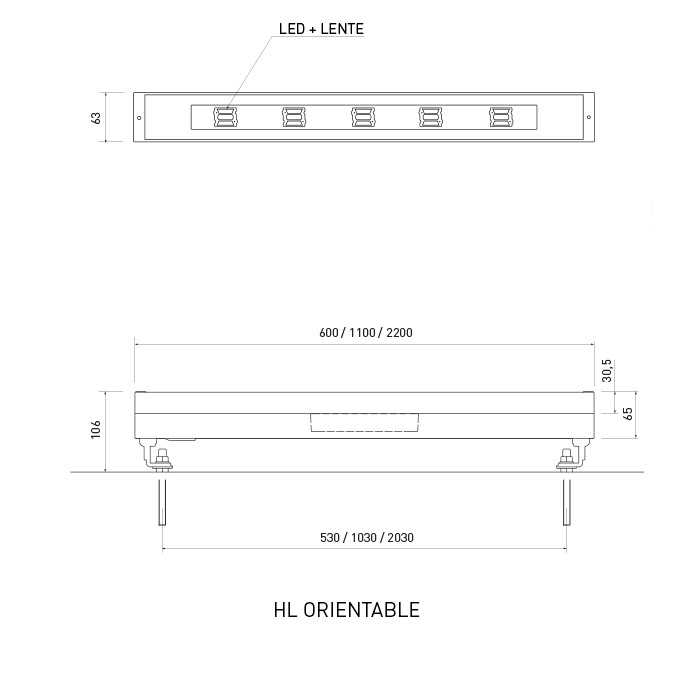

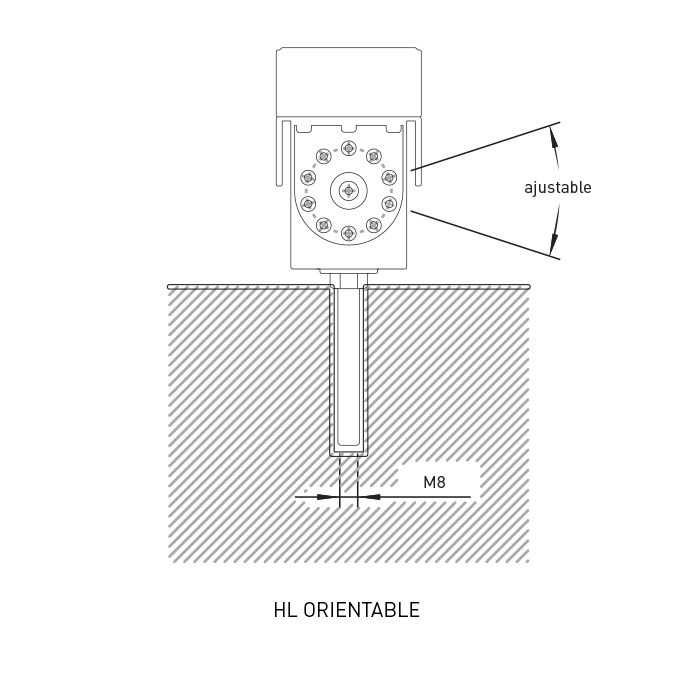

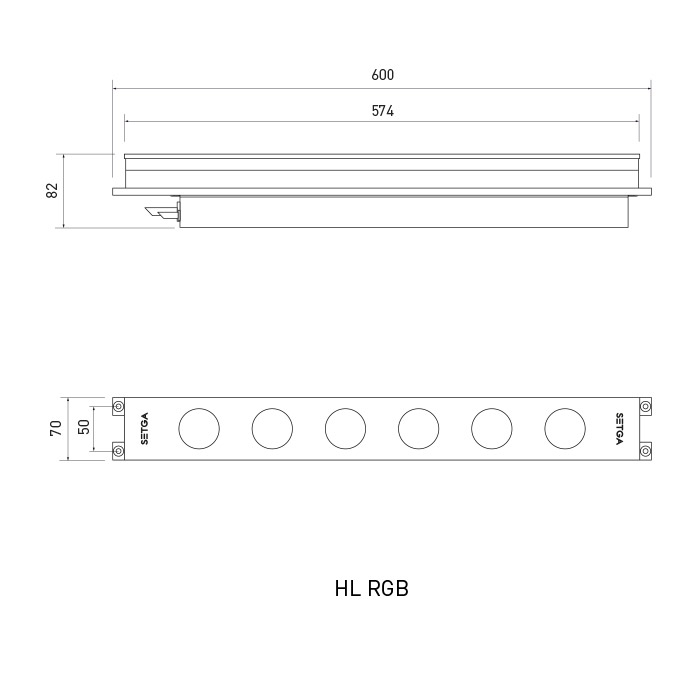

Dimensions

Here are the basic dimensions of the HL series:

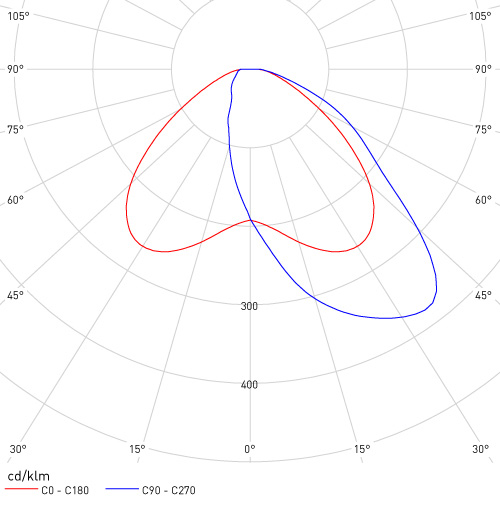

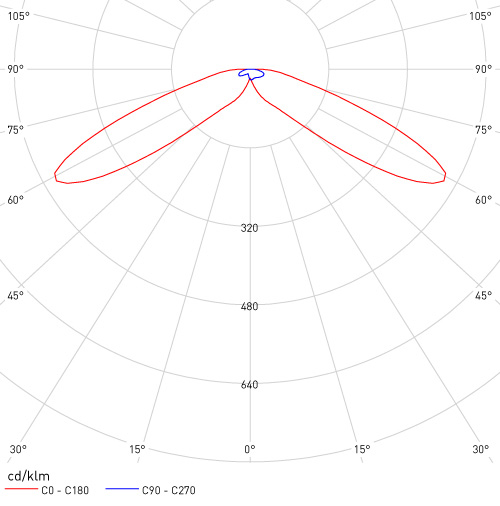

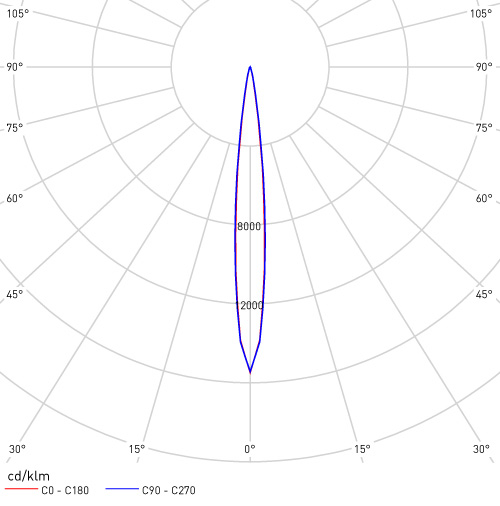

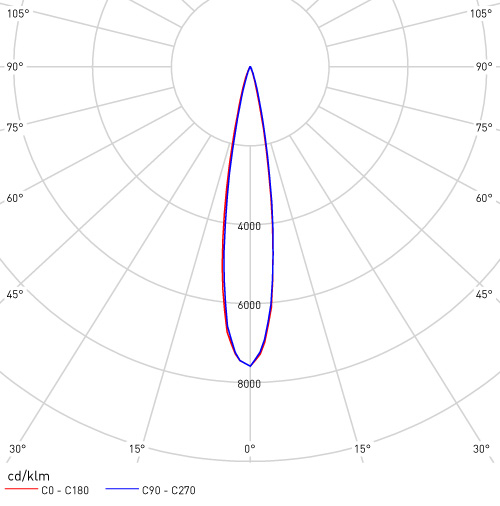

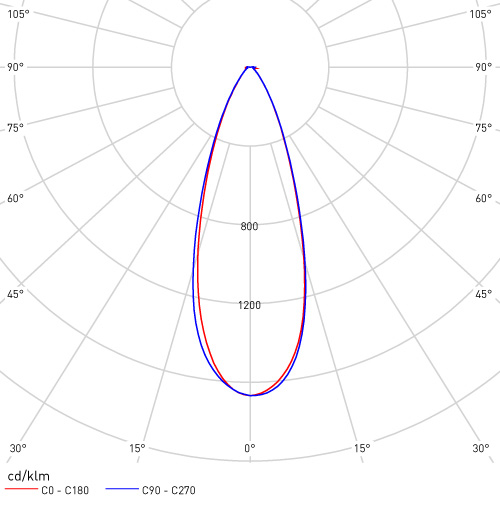

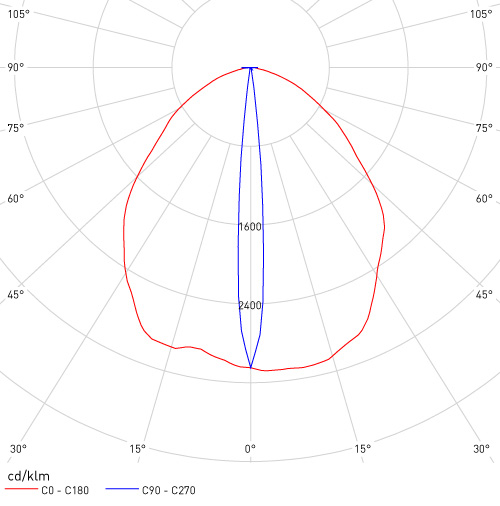

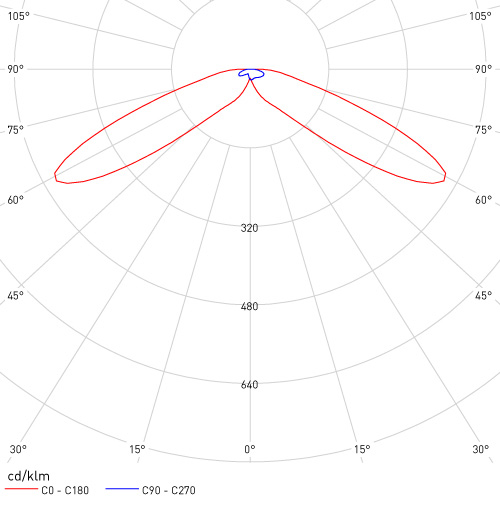

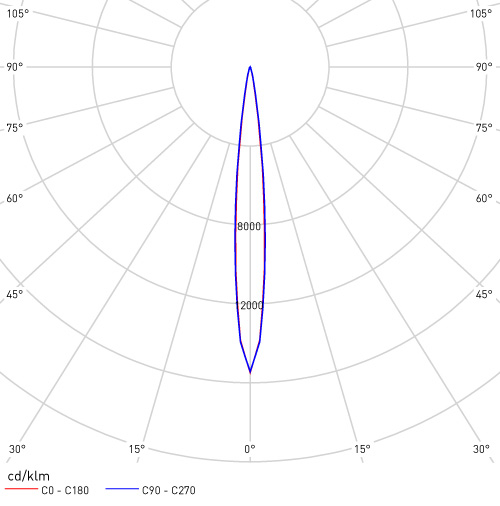

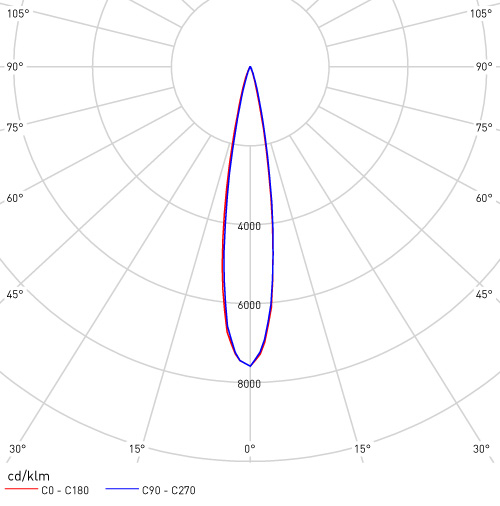

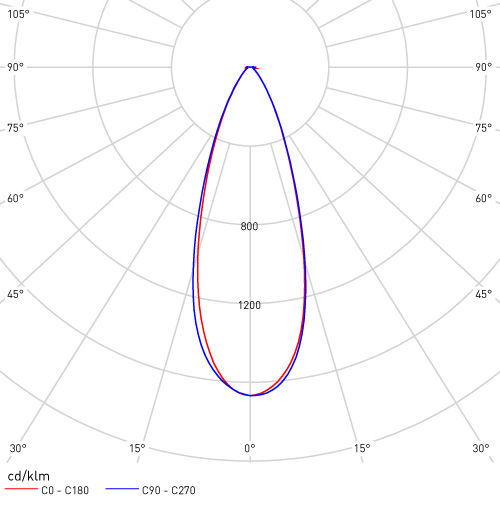

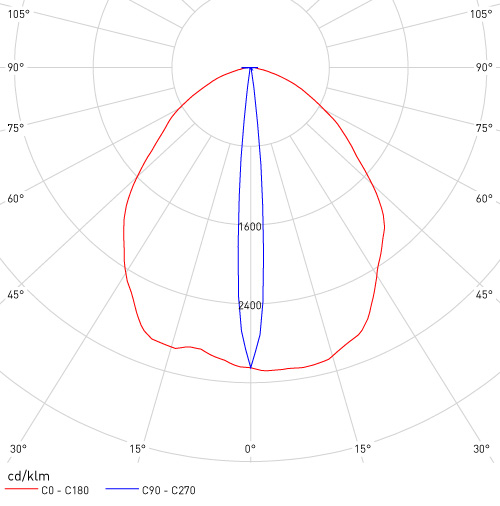

Photometry

Standard Photometries. The SETGA optical department can study additional configurations adapted to each project.

Iconic projects

OURENSE ROMAN BRIDGE LIGHTING

Ourense Roman Bridge

Do you have a technical question?

Ask us