ESSENZE-P

ESSENZE-P

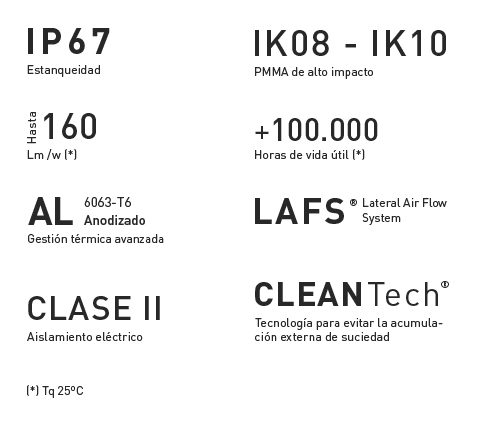

PresentationTECHNOLOGICAL ROBUSTNESS

The design integrity inherent to the Essenze series has triggered a new rationalist language, where form follows function, preserving the honesty of advanced materials and the contrast of every detail, expanding performance boundaries from reliability and technological robustness.

ORIGIN AND EVOLUTION

The intelligent integration of various aesthetic and industrial trends has transformed the technological status quo, creating a new relationship between light and urban space.

SETGA has merged contemporary trends in the automotive industry with the aesthetic of Central European watchmaking to create a compact format, harmonizing the dynamic nature of the unit with the contrast and robustness inspired by each mechanical component. This dialogue between efficient rationality and technical precision defines a new urban dimension through which the luminaires grow in the longitudinal direction of the roadway, harmonizing the visual perspective of the observer.

MATERIALS AND STRUCTURE

The compact aluminium AL 6063-T6 extruded and anodized body minimizes the degrading effect of aggressive environments. The column anchoring system is characterized by high structural reliability. A robust locking mechanism, close to the centre of gravity of the luminaire, eliminates the front tilting risk inherent to any large format. Finally, the set of injected aluminium end caps and Stainless Steel screws through which the sliding driver system is accessed has been designed to prevent fasteners from loosening during the extraction process, speeding up maintenance and preserving thread effectiveness over the lifetime of the luminaire.

SUSTAINABLE DESIGN

Each new luminaire in the Essenze series is the result of a highly sustainable industrial process, distinguished by its recycling capacity and optimization of applied materials. When compared to other processed aluminium, aluminium 6063-T6’s high purity ensures full reuse by other industries in future. Additionally, the high thermal conductivity of this material allows for component size adjustment, resulting in advanced thermal performance with lower material density than bodies manufactured from other aluminium. Following the latest ISO 14001 audit, and the implementation of the master plan for sustainability, SETGA has driven the design of a long-term recycling system for each Essenze component.

Technical keys

In order to optimize the heat dissipation process, enhance efficacy (lm/W) and increase luminaire lifetime, SETGA has developed a pioneering system by integrating an internal structure of heat pipes and a lateral cooling mechanism (LAFS®) within a single compact body sink made of extruded and anodized aluminium AL 6063-T6. The Essenze luminaire is equipped with continuous, accelerated and self-refrigerated thermal architecture capable of reducing LED junction temperature between 5° C (350mA) and 15° C (700mA) in relation to standard systems manufactured in die cast aluminium.

According to the US Energy Agency, relief on the upper surface of the fixture severely hinders the dissipation process that takes place by convection, becoming a critical element for performance and life.

To overcome this challenge and to enhance the natural self-cleaning process, SETGA has equipped the Essenze luminaire heat sink with a completely uniform and curved upper surface, thus preventing dirt accumulation, and the ensuing obstruction and inefficiency of the thermal dissipation system. Finally, baffles located on the lower front and rear surface of the optical area prevent dirty liquid flowing from the upper area of the body to the lenses, thereby preserving optical system efficiency (lm/W).

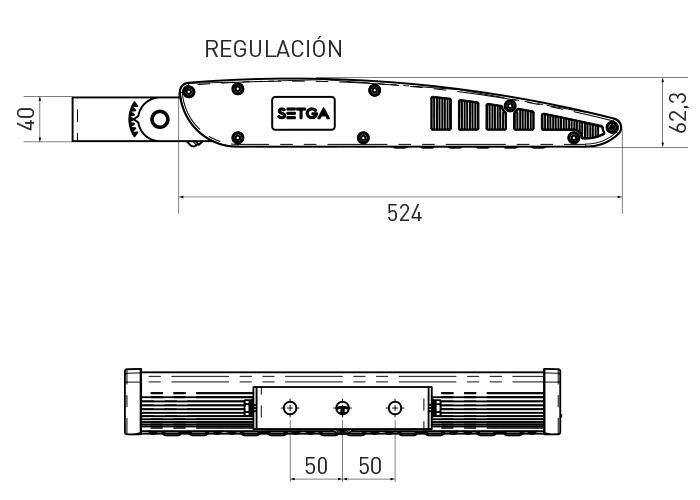

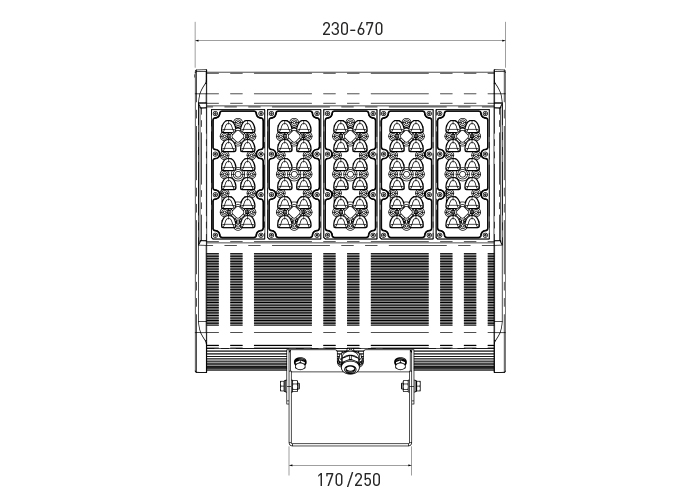

Dimensions

Here are the basic dimensions of the ESSENZE-P series:

Do you have a technical question?

Ask us

.jpg)

.jpg)