DIVERSITY

DIVERSITY

PresentationEVOLUTIONARY MODERNITY

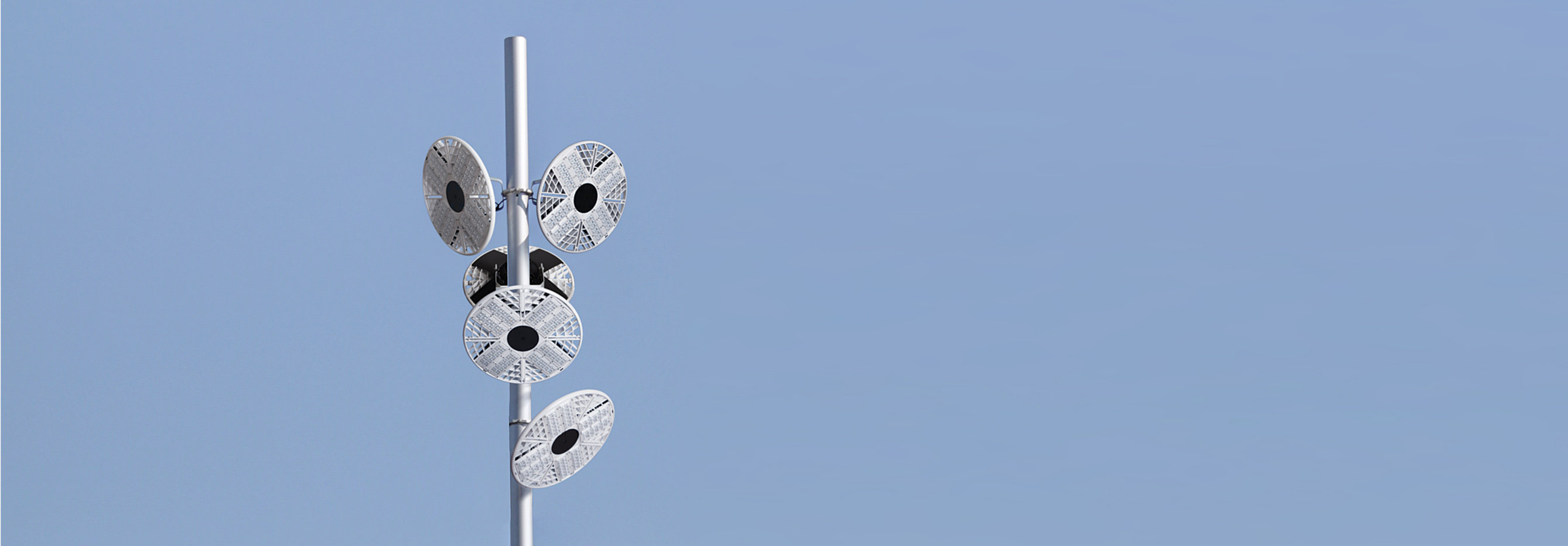

Functionality shaped by avant-garde at the service of urban comfort. This is the genesis of Diversity, the awakening of a LED generation where visual subtlety drives integration into a wide variety of outdoor applications.

ORIGIN AND EVOLUTION

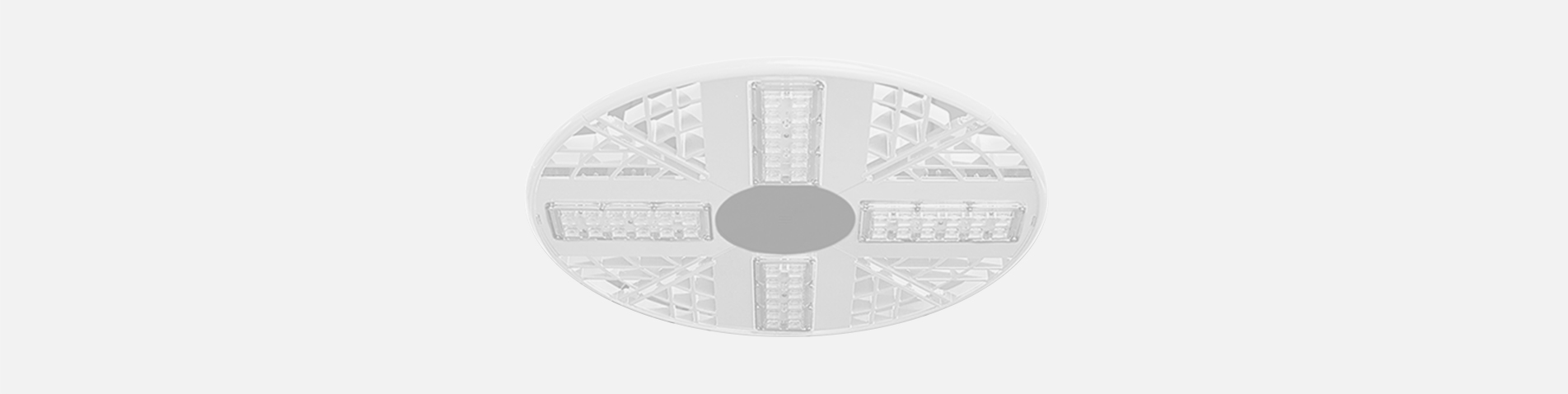

The Diversity illustrates modularity and versatility, defining authentic spaces that transcend over time. Circular geometry and compact design evoke timeless values. The fusion between straight and curved lines connected through discrete intersections lend modernity to the whole set. In this aesthetic exercise, design also promotes effectiveness and efficiency, enhancing thermal self-cooling and dissipation, as well as optical customization capabilities.

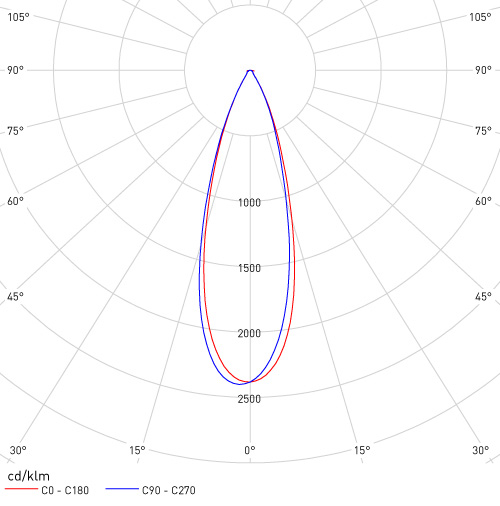

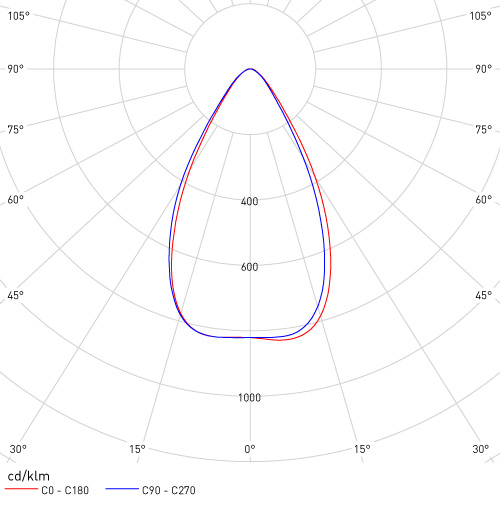

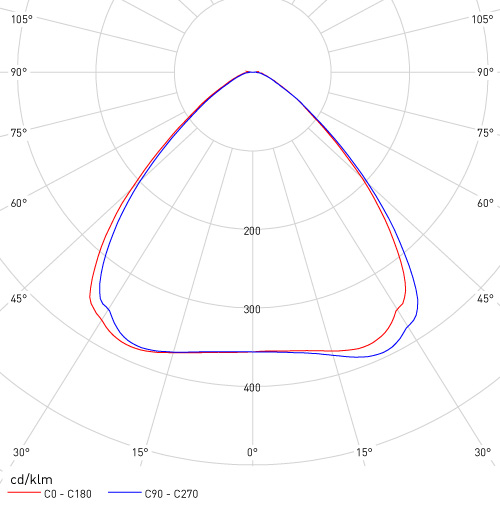

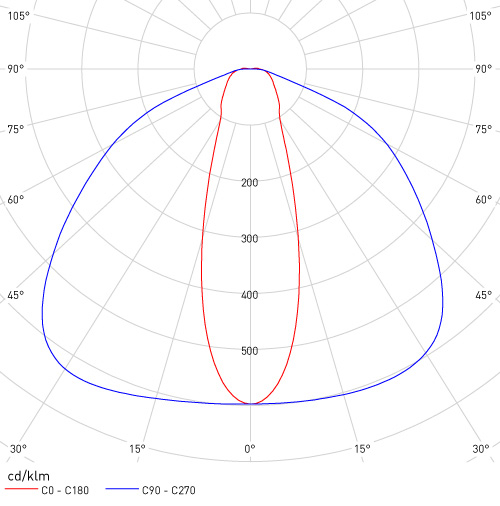

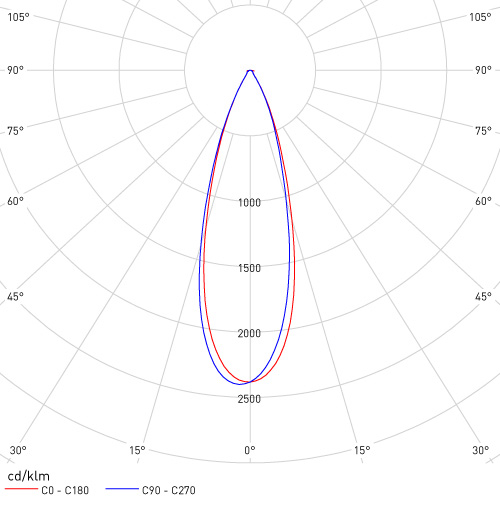

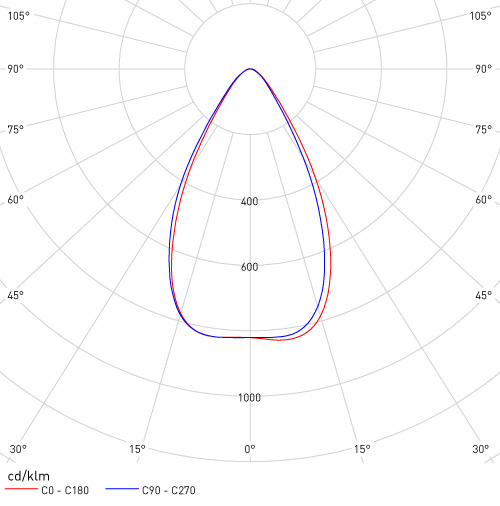

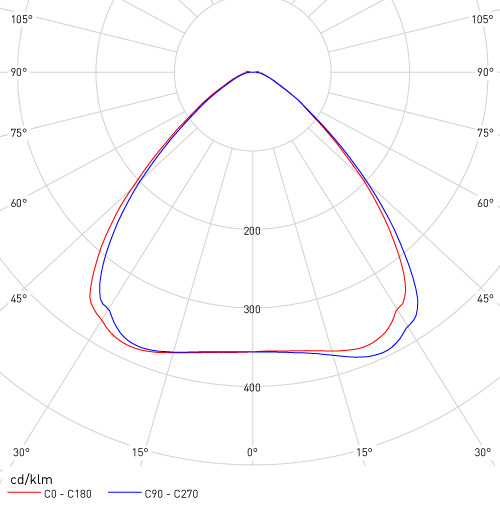

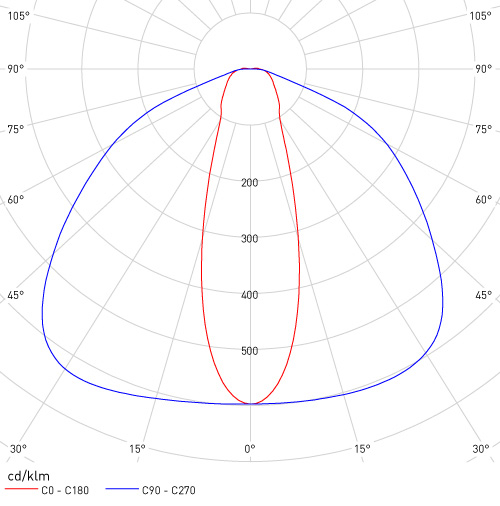

The lenses are arranged in the form of a Greek cross, generating a wide variety of photometric possibilities and optimizing highly complex layouts.

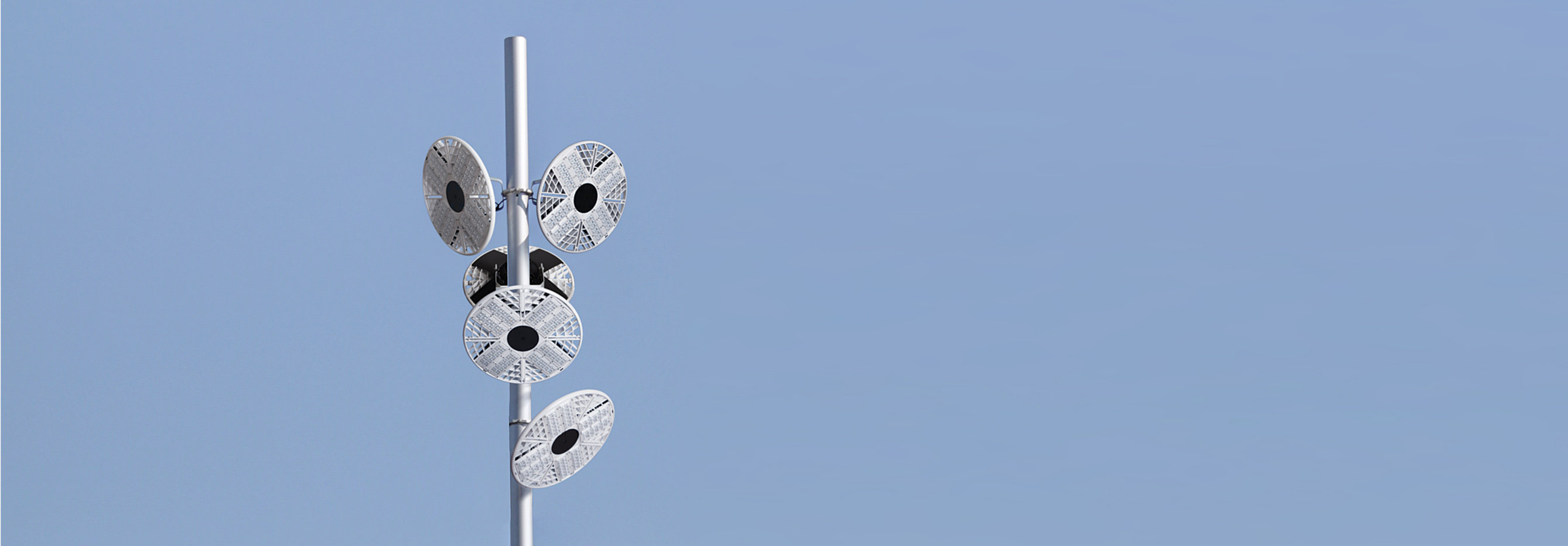

MATERIALS AND STRUCTURE

The main structure is shaped by an EN AC-44100 injected aluminium body. The material is free of copper alloy, thereby increasing resistance to corrosion compared to most existing market injections. In highly aggressive environments, optional anodizing substantially extends the life cycle of the body.

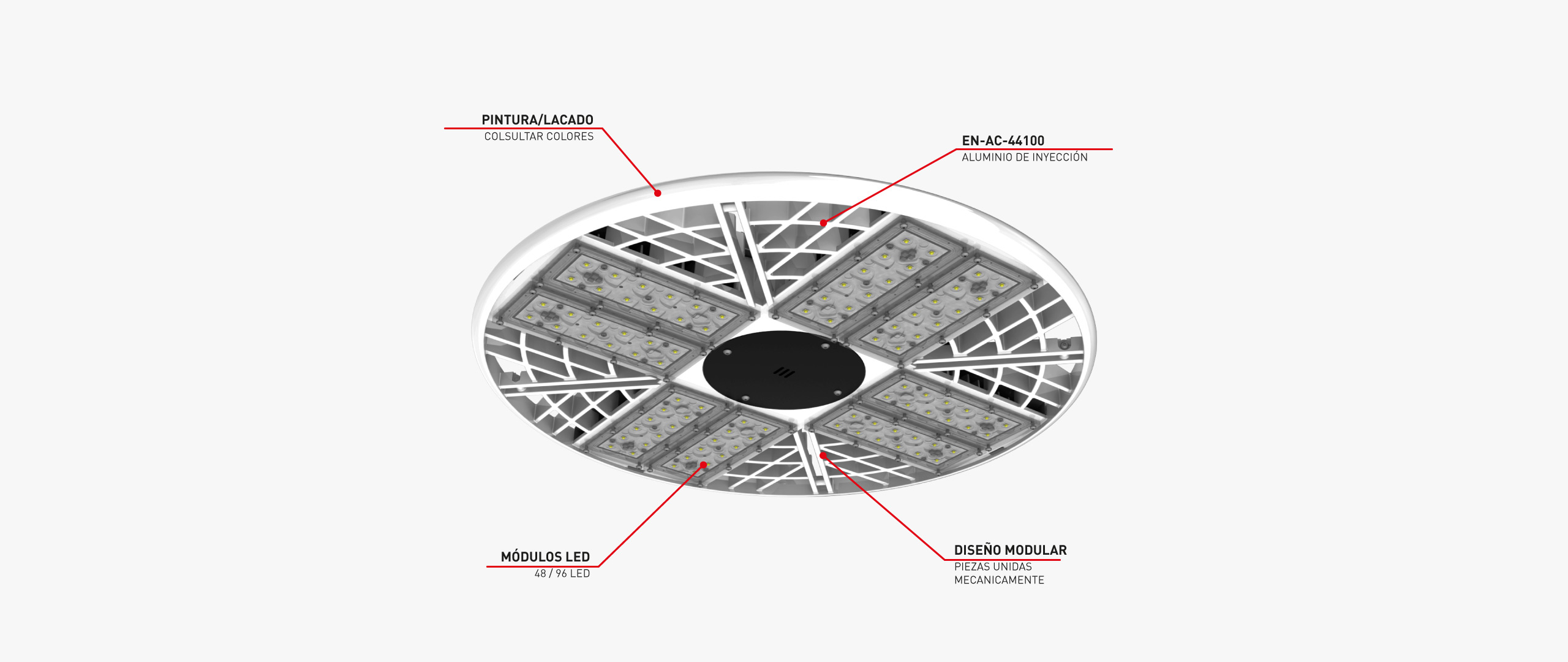

The configuration of the mechanical structure creates a thermal bridge between the dissipation area of the LED module and the power supply, avoiding critical heat transmission, which characterizes a large number of standard architectures.

Technical keys

The LAFS® (Lateral Air Flow System) side cooling system generates an internal convection process to reduce the temperature of thermal critical areas, where the luminaire body comes into direct contact with the PCB. Finally, the use of a graphite thermal pad in the area between the PCB and dissipation body contributes to thermal contact optimization between both elements, eliminating air gaps and improving the dissipation process in the early stages.

According to the US Energy Agency, relief on the upper surface of the fixture severely hinders the dissipation process that takes place by convection, becoming a critical element for performance and life.

To overcome this challenge and to enhance the natural self-cleaning process, SETGA has equipped the Diversity projector with completely uniform surfaced special pieces, installed over the dissipating fins, thus preventing dirt accumulation, and the ensuing obstruction and inefficiency of the thermal dissipation system. At the same time those pieces allow the natural flow of dissipated heat by the fins through both open sides.

The dissipation system of the Diversity projector has a very high dissipation and cooling capacity. This responds to several reasons, its high dissipative mass and its high exposed surface due to its hollow lattice design.

It is made up of 4 identical modular pieces and assembled in a solidary and permanent way, forming a rigid dissipative assembly of injected aluminum EN-AC-44100 (L-2520).

The complete elimination of air gaps between the PCB and the heatsink body favors thermal contact between both elements. To achieve this, the dissipating body is initially machined and ground, thus ensuring an optimum level of flatness and surface roughness. Subsequently, the previously mentioned graphite "thermal pad" is incorporated into said meeting area in order to achieve an intimate level of union.

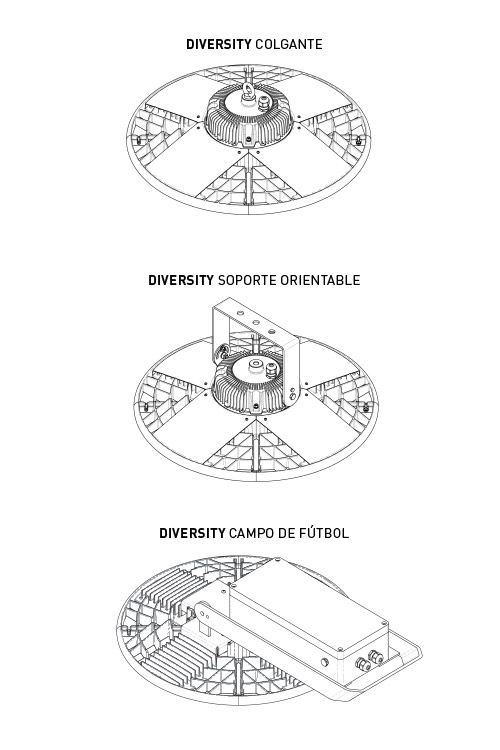

Descriptive views

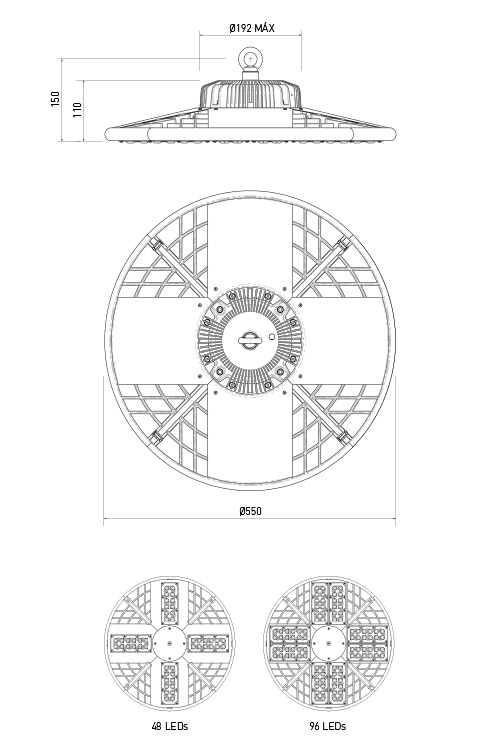

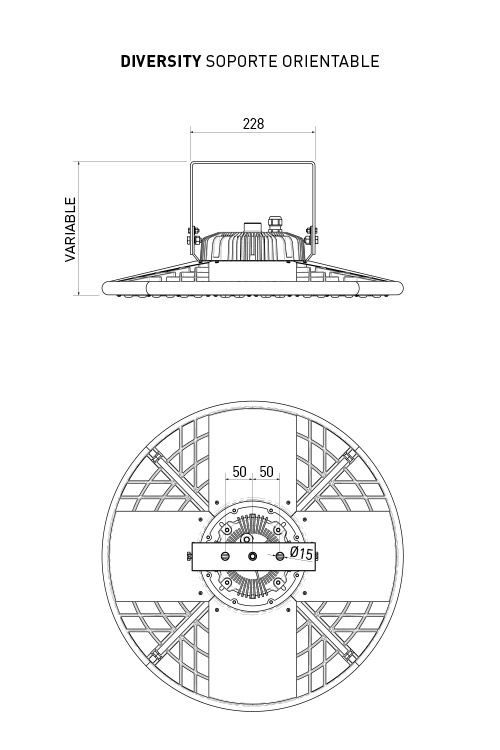

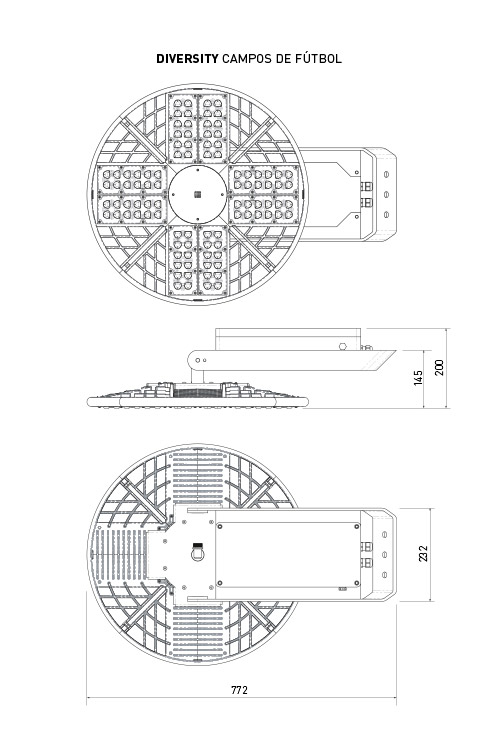

Dimensions and installation

The Diversity luminaire has an outside diameter of 550mm and a variable height depending on the driver installed.

This product can be anchored in various ways, it can be provided with a hanging ringbolt or with an adjustable bracket of various sizes.

It exists in 48 and 96 LED versions and with different power and lens regulations for even the most demanding applications such as outdoor sports fields.

Its installation is done with M12 screws or hanging ringbolts.

![]()

Creators

Jesús Saavedra

Chief Innovation Officer (SETGA)

Francisco Paz

Thermodynamic Engineer (SETGA)

Do you have a technical question?

Ask us

.jpg)

.jpg)