ADM

ADM

PresentationTHE POWER OF CONTRAST

Enhancing city diversity calls for the application of elements capable of generating shades and contrasts in line with the desired atmosphere. A genuine fusion of materials is the ADM series’ response to the contemporary challenges of urban regeneration.

ORIGIN AND EVOLUTION

The ADM series was initially conceived to enhance the urban welcome experience, providing main access avenues with a range of contrasts based on the integration of an upper body in the shape of a light beacon and the combination of a polished Stainless Steel fixture, with an extruded aluminium column.

The incorporation of the latest LED technology has underscored the capacity of the ADM series design line to further enhance the identity of the most avant-garde environments in the era of smart cities.

MATERIALS AND STRUCTURE

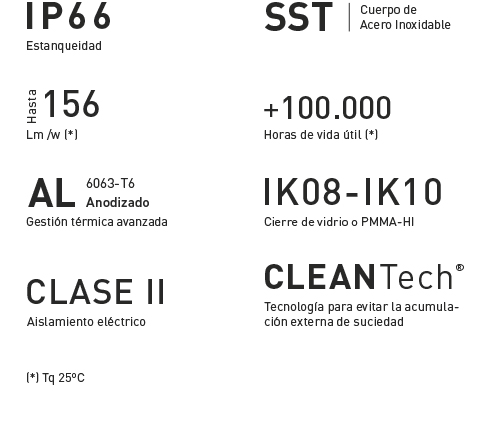

The ADM luminaire body is made of AISI304 or AISI316 Stainless Steel to prevent the degrading action of highly aggressive environments, such as coastal areas. The interior houses an extruded, anodized aluminium 6063-T6 chassis, acting as a thermal sink.

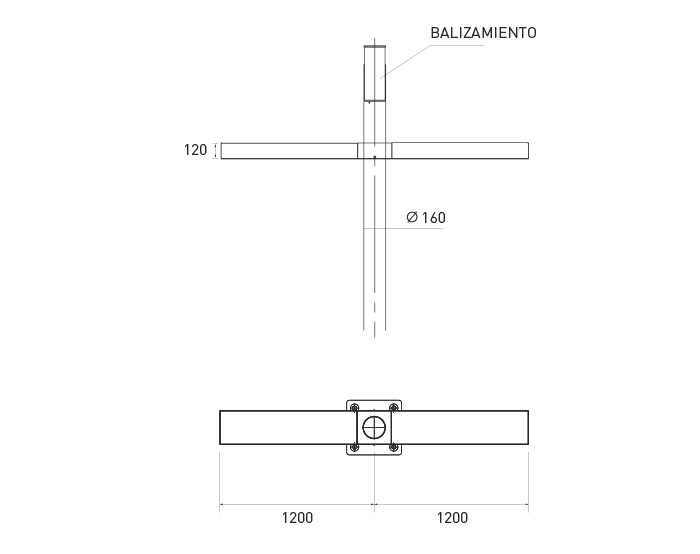

The luminaire is integrated into the ADM extruded and anodized aluminium, cylindrical section column (9 m, standard height), and is adaptable to the requirements of each project. An innovative anchoring system provides flexibility to vary luminaire height at any time.

SUSTAINABLE DESIGN

The AMD luminaire incorporates one of the world’s most recycled materials—steel. Reintroducing steel to the production cycle of other industries at end of useable life will produce significant energy savings compared with other metals. Unlike aluminium injection, for example, extruded aluminium used for manufacturing the chassis sink facilitates reuse in other product categories. Following the implementation of ISO 14001 and the development of the sustainability master plan, SETGA has striven to reduce the carbon footprint of all its components, by designing a long-term recycling system for each one.

Technical keys

The ADM luminaire is based on the principle of direct thermal dissipation between the LED PCB and the compact aluminium chassis. The dissipation body comprises a continuous heat pipe of anodized aluminium 6063-T6, which achieves thermal conductivity levels of 200 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection. The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

According to the US Energy Agency, relief on the upper surface of

the fixture severely hinders the dissipation process that takes place by convection, becoming a critical element for performance and life.

To overcome this challenge and to enhance the natural self-cleaning process, SETGA has equipped the ADM luminaire with a completely uniform upper surface, thus preventing dirt accumulation, and the ensuing obstruction and inefficiency of the thermal dissipation system.

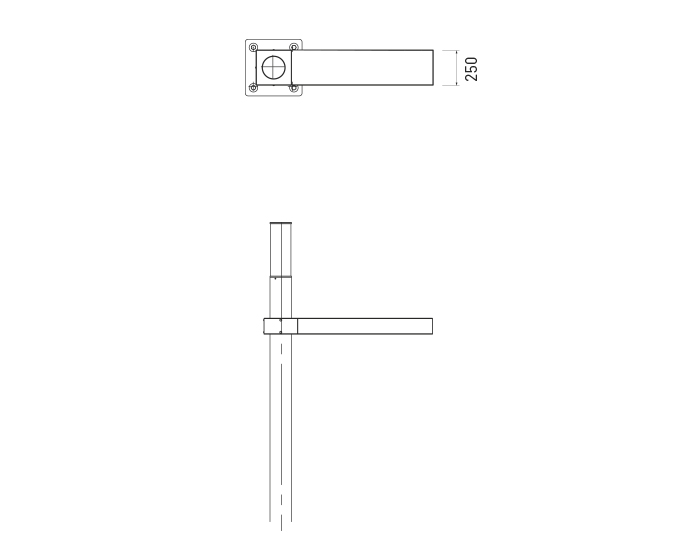

Dimensions

Here are the basic dimensions of the ADM series:

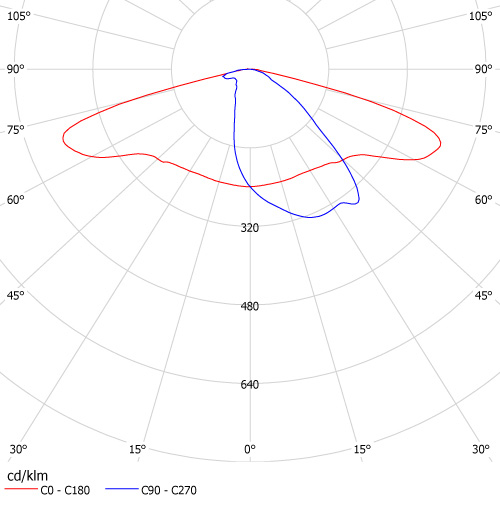

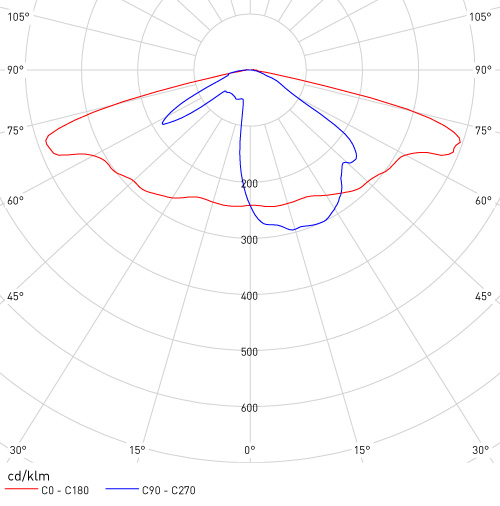

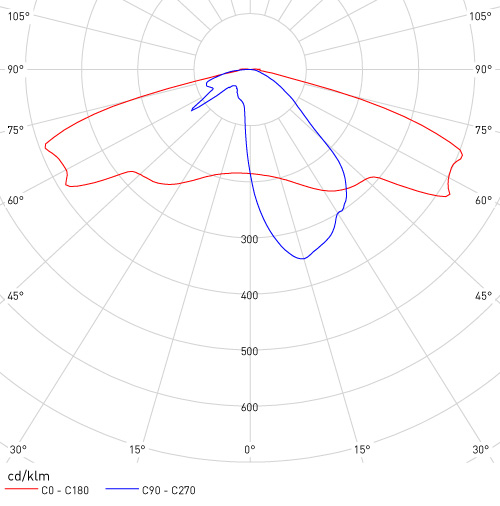

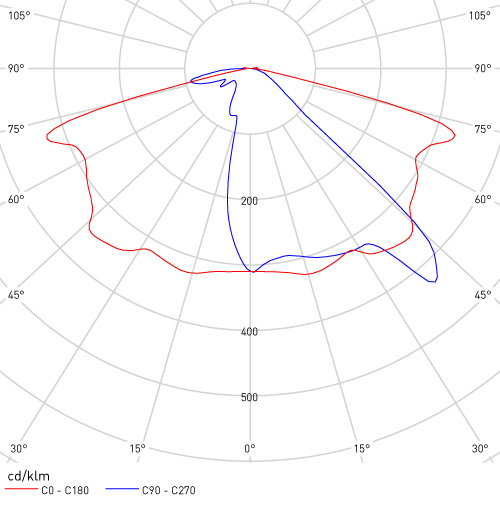

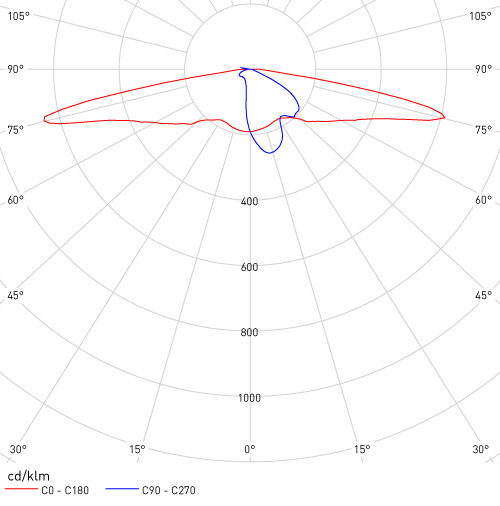

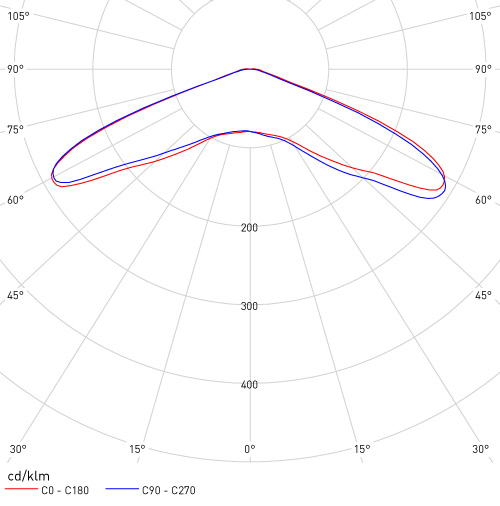

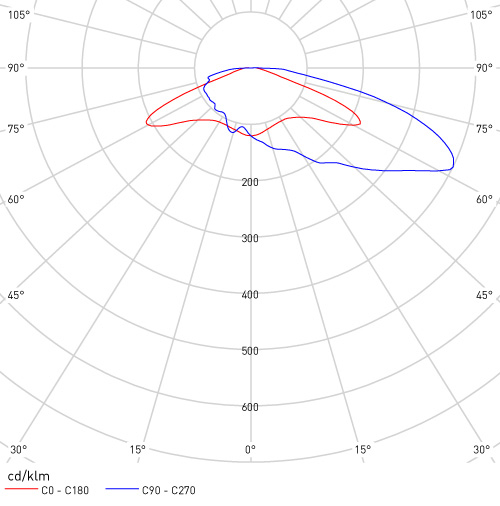

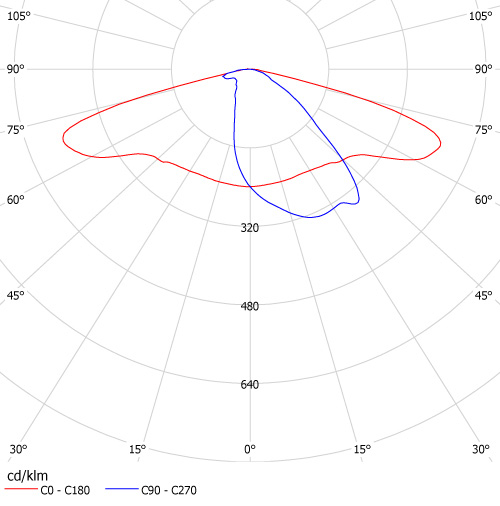

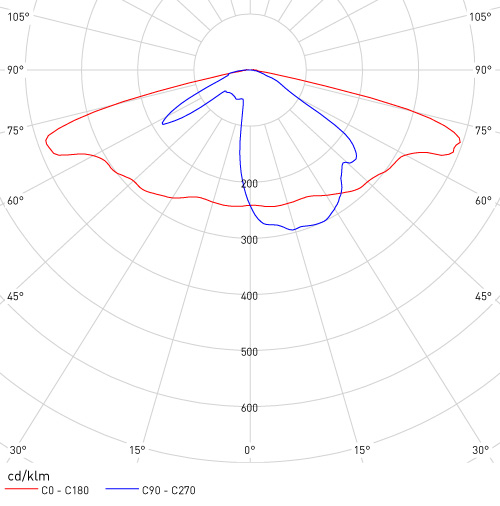

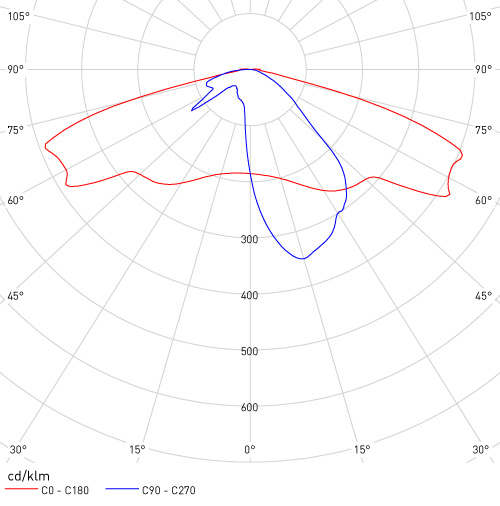

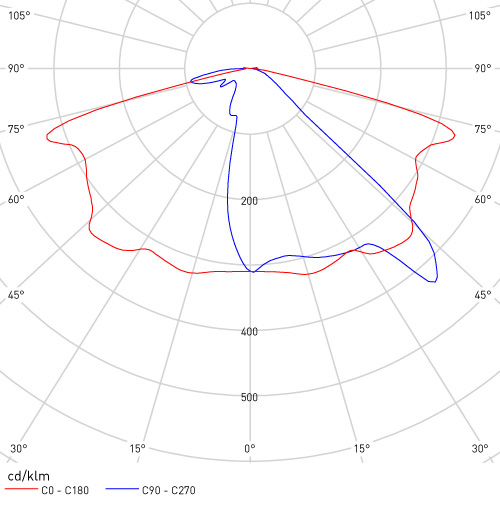

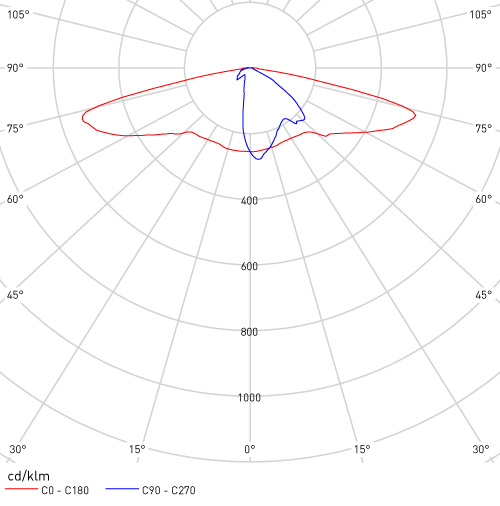

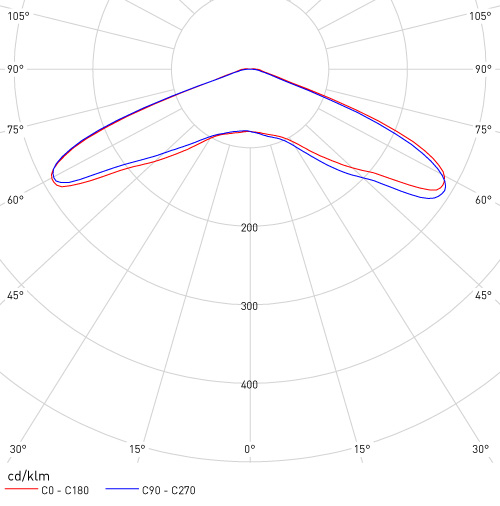

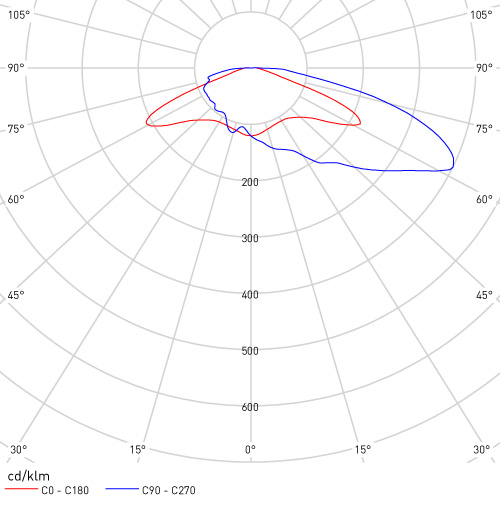

Photometry

Standard Photometries. The SETGA optical department can study additional configurations adapted to each project.

Do you have a technical question?

Ask us