QUANTUM

QUANTUM

PresentationTOWARDS A NEW GENERATION

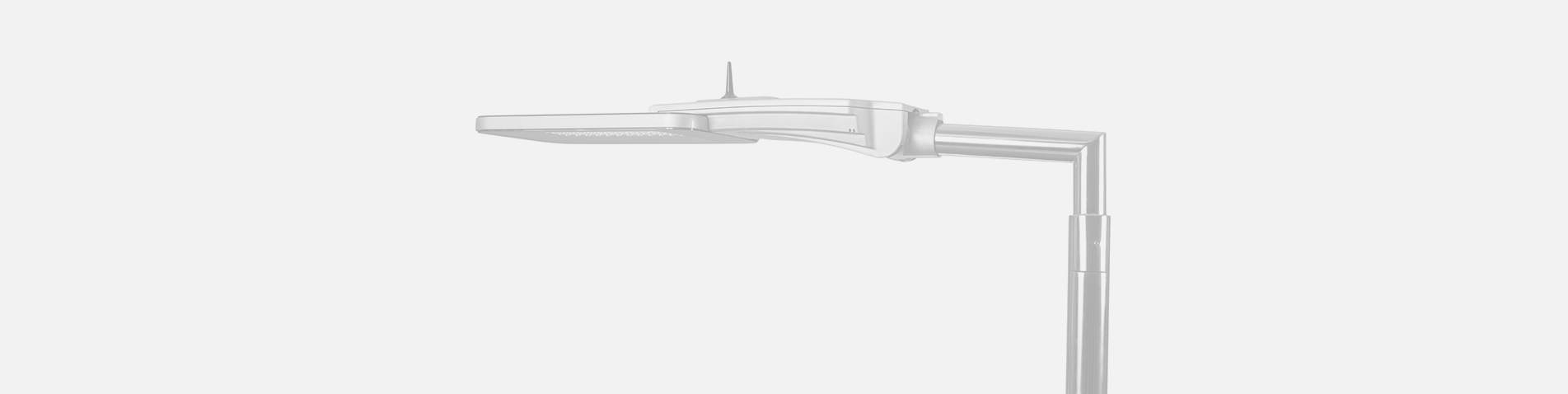

Fluidity and dynamism bring to life to a new generation of LED lights set to redefine functional public lighting through the application of technological vanguard and biomimetic design, combining reliability, high performance and visual comfort without sacrificing the modular essence of the elements.

ORIGIN AND EVOLUTION

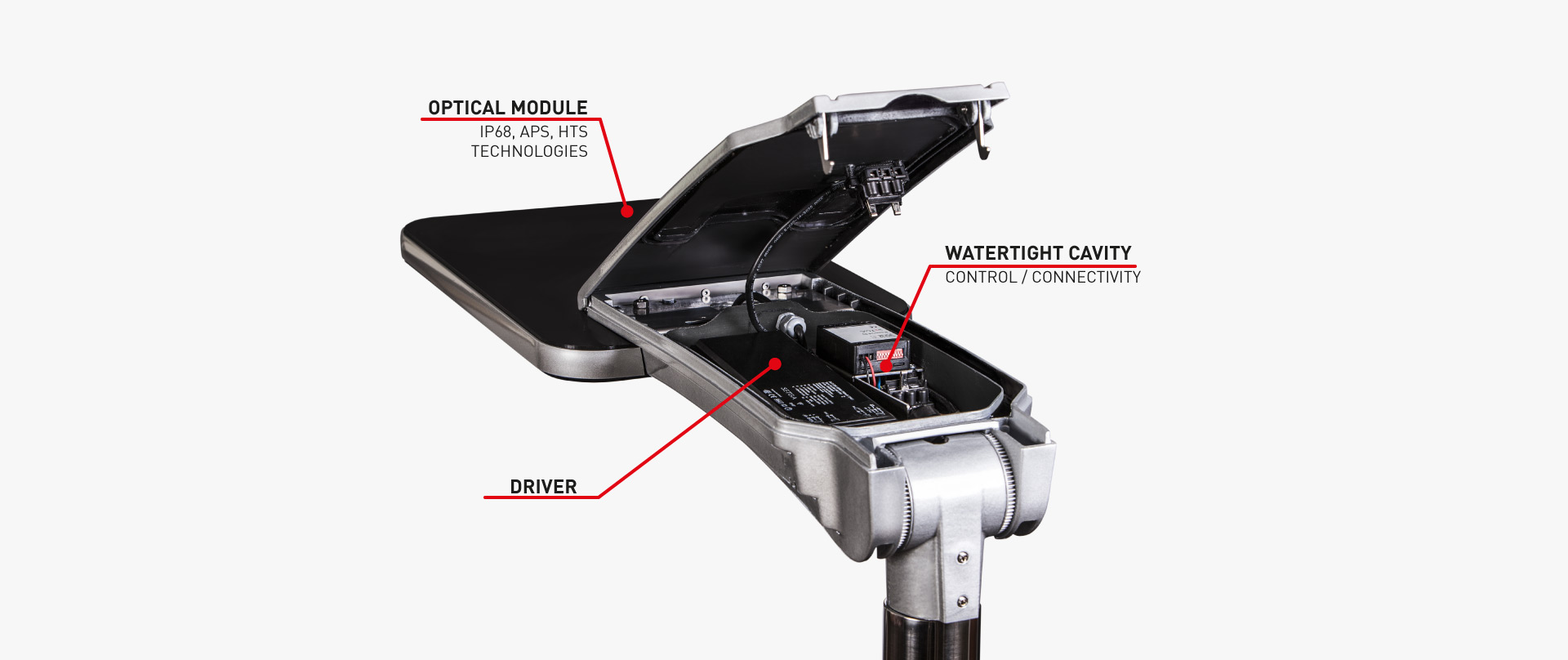

Very much in keeping with SETGA’s DNA, Quantum’s subtle lines combine an innovative mix of curved and straight forms that transform the irregularities of nature into aesthetic fluidity and continuity. This exercise in biomimetic design brings harmony and dynamism to the whole, while bestowing a compact and sober appearance on the element modularly structured into two separate bodies: the optoelectronic LED module pressurized with APS® argon gas and a rear high capacity airlock conceived to house a wide variety of auxiliary electronic equipment. In Quantum, the technological reliability of the APS® system proven over the last eight years is as important as the accessibility and agility of future maintenance processes. The LED module extraction time is therefore reduced by 90%, from 30 to 3 minutes, and only involves acting on two anchors.

MATERIALS AND STRUCTURE

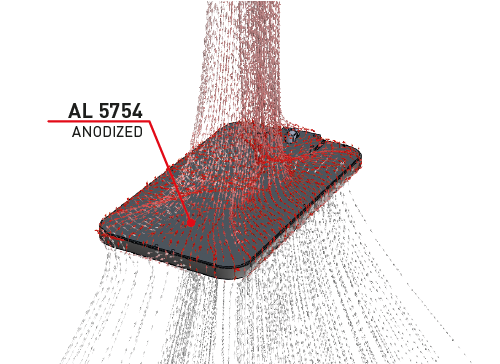

The rear compartment of the structure is composed of an EN AC44100 injected aluminium body. The material is free of copper alloy, thereby increasing resistance to corrosion compared to most existing market injections. In highly aggressive environments, optional anodizing substantially extends the life cycle of the body. The upper body of the optoelectronic module consists of anodized AL 5754 aluminium, which acts as a direct heat dissipation mechanism and is noted for high resistance to corrosion. An R43 closure of tempered glass is applied to the lower surface. Structural strength and minimal exposure of the side surface along the entire luminaire enable Quantum to withstand winds of 180 km/h, exceeding the resistance of 150 N/m2 established by the standard.

SUSTAINABLE DESIGN

The sustainable design strategy of the Quantum series is part of SETGA’s upgrade program and responds to a circular public infrastructure management model, whereby the life cycle of mechanical components exceeds the obsolescence curve of LED technology. When the future upgrade of the optical module becomes profitable through the evolution of efficiency, the rear body will remain in the public space while SETGA updates the optoelectronic module in optimal and controlled atmospheric conditions, ensuring immediate replacement. 100% natural glass makes this material fully recyclable, thereby minimizing the environmental impact of its transformation process. Finally, with the support the first European glass processing line powered by solar technology, the carbon footprint of this series has been substantially reduced.

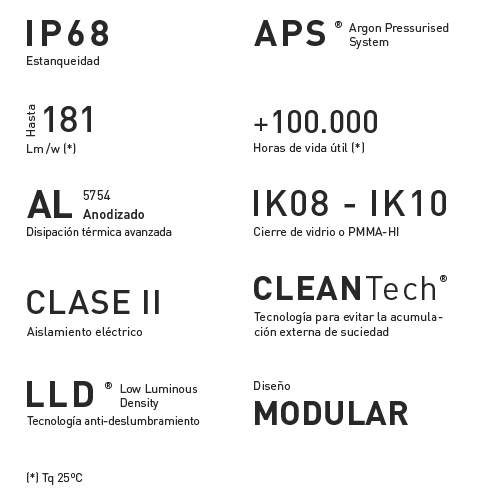

Technical keys

With the Argon Pressurised System (APS)® Quantum series’ optical and electronic components are encapsulated in a pressurized atmosphere of argon gas. A watertightness level of IP68 is ensured, making the system resistant to complete and continuous immersion far beyond the requirements of any regulation.

The inert atmosphere in the optical-electronic module guards against condensation, moisture and salinity intrusion, thereby preventing an accelerated ageing process of the system’s sensitive components. This protective shield is essential in areas where air salinity is a critical lifetime factor for any optical and electronic component.

The ability of this system to preserve the lifetime, efficacy and chromatic quality of the luminaire reduces Up toal Cost of Ownership (TOC) and maintains high demanding visual comfort standards.

The Quantum luminaire is based on the principle of direct thermal dissipation between the LED PCB, the compact aluminium chassis and the exterior. The luminaire body comprises a continuous heat pipe of AL 5754 anodized aluminium, which achieves thermal conductivity levels of 160 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection. The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature.

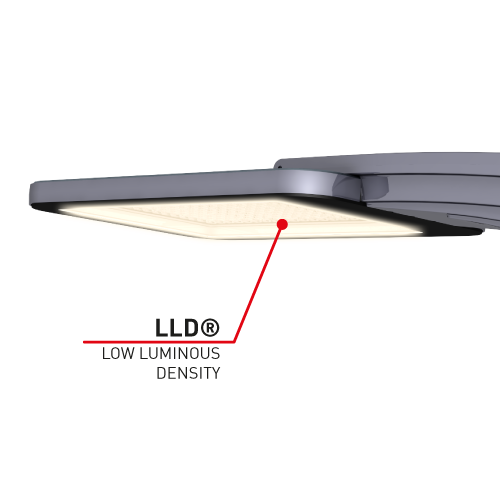

LLD technology improves the glare index (GR) without the need for optical systems characterized by reflection or refraction processes whose efficiency levels (lm/W) experience significant losses. Quantum distributes low power LED diodes below 1 W along the optical module, increasing the light emitting surface size to reduce luminous density in all solid angles of observation.

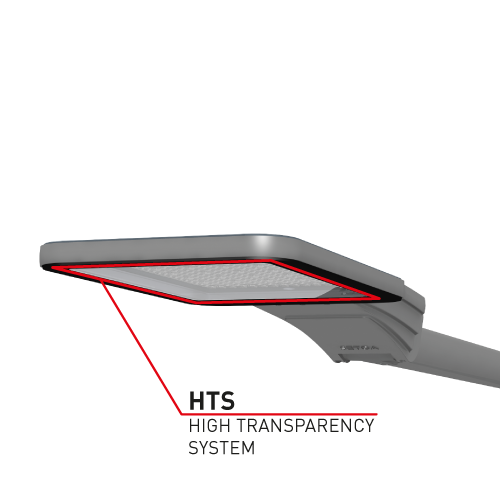

The redefined composition of the optical system delivers a 55% reduction in reflection levels, a significant drop when compared with market standards that apply a secondary lens scheme and a tempered glass cover. HTS technology enables optical performance levels similar to those obtained with a direct lens system, increasing the overall efficacy of the luminaire (lm/W) by 8%.

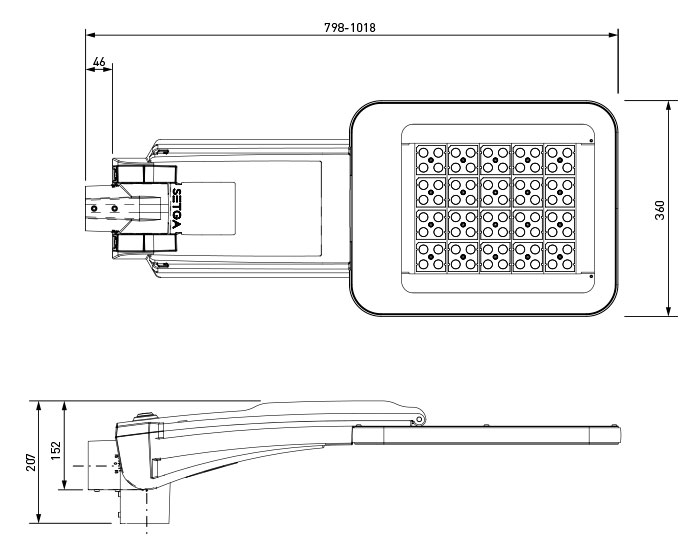

Descriptive views

Dimensions and installation

The Quantum length dimensions in current models range from 798 to 1018 mm. The width remains unchanged and the height will depend on the anchor position chosen.

The design of the Quantum allows both installation in horizontal and vertical arms and a regulation of ± 15 °. Allows mounting on supports up to Ø60 mm. Its installation requires only an Allen key.

Its modular design and its opening and anchoring system allows a quick replacement of the optical module or another component in case of failure.

![]()

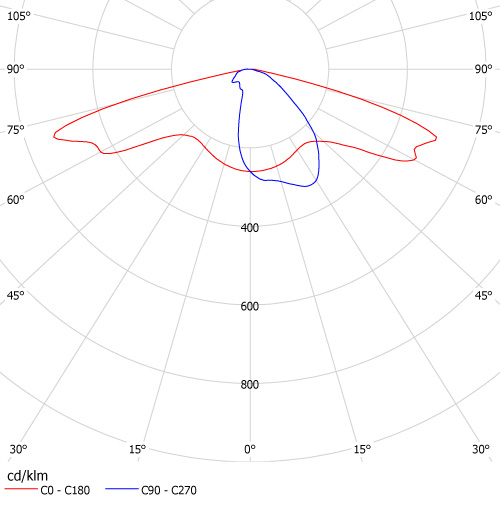

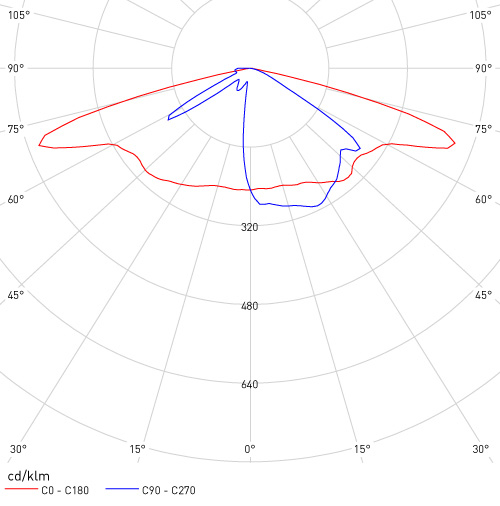

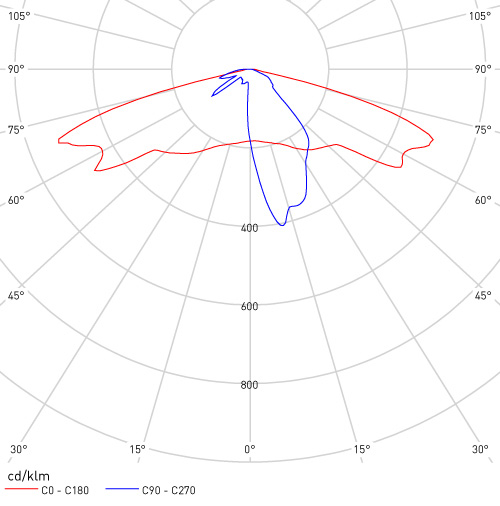

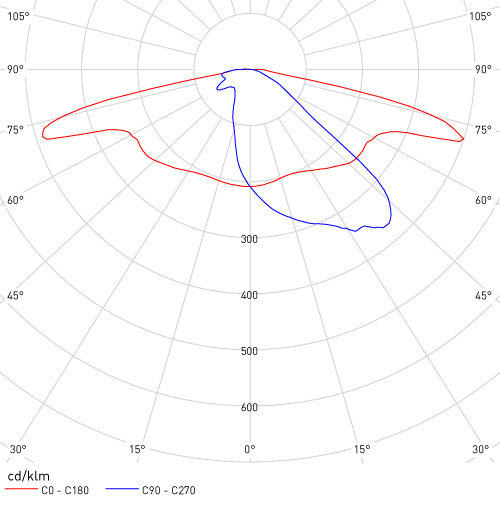

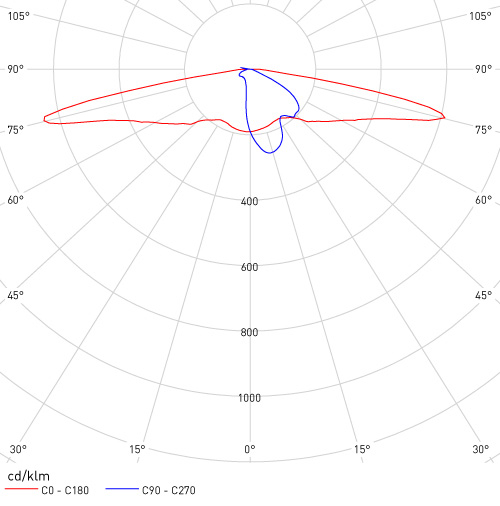

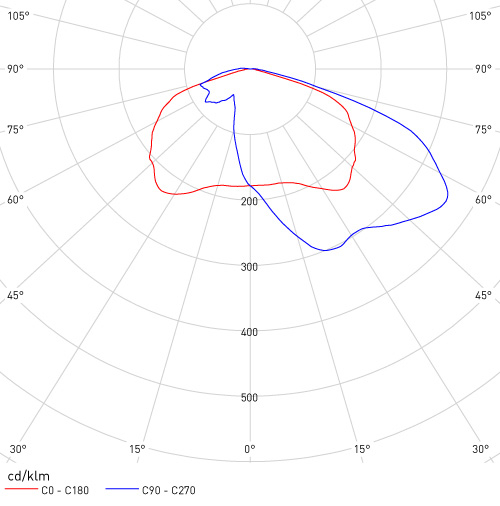

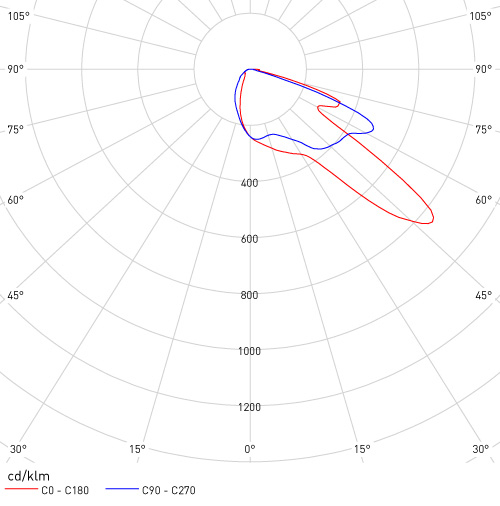

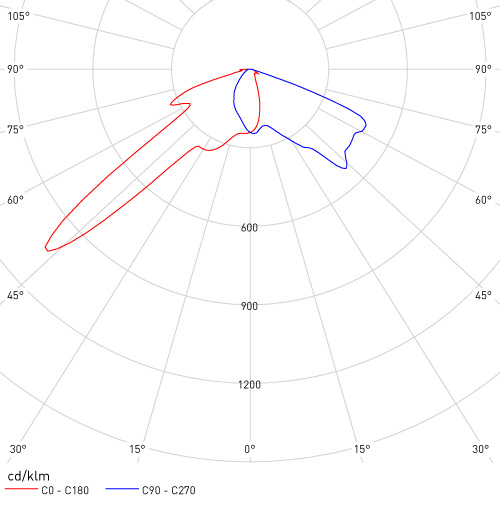

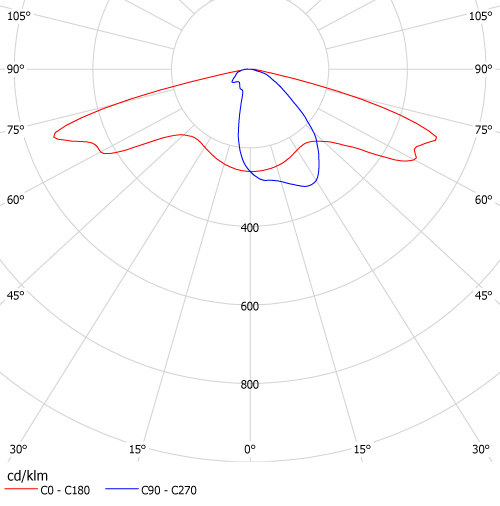

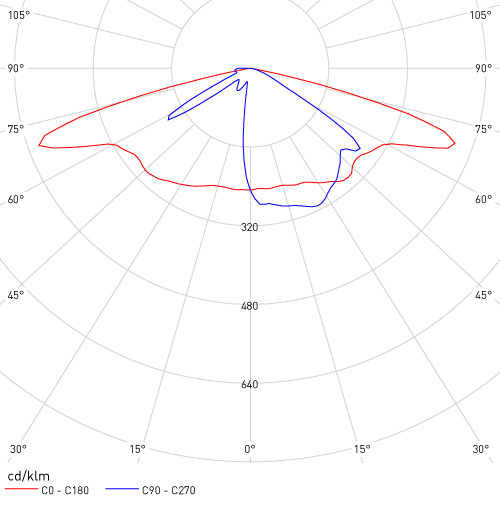

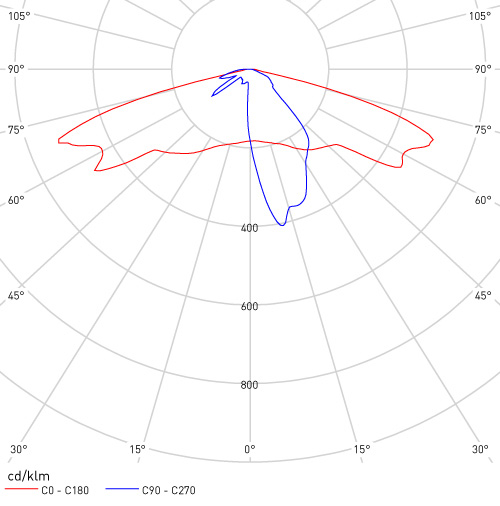

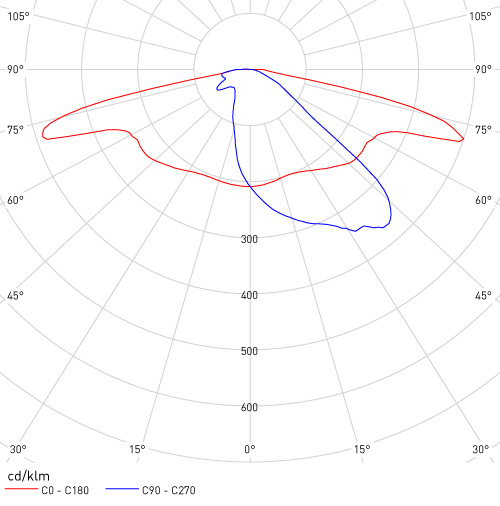

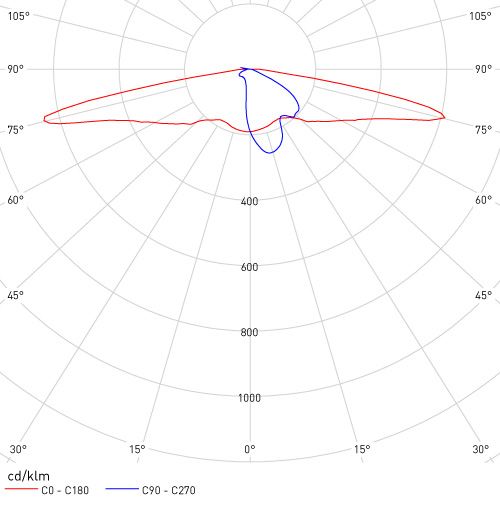

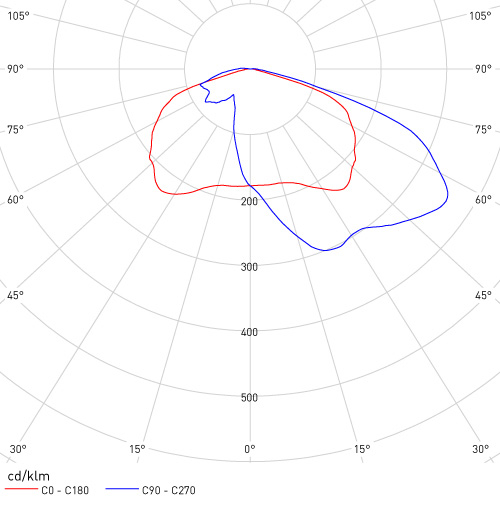

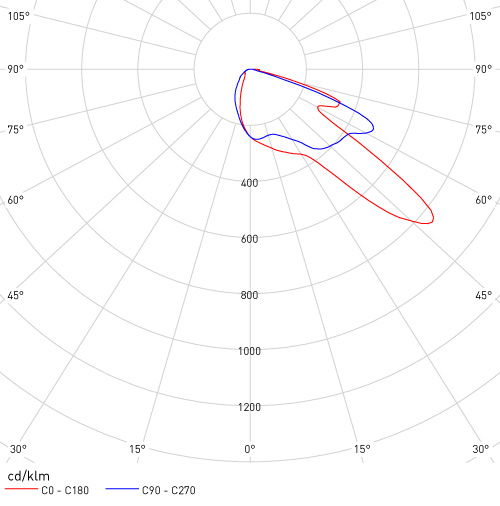

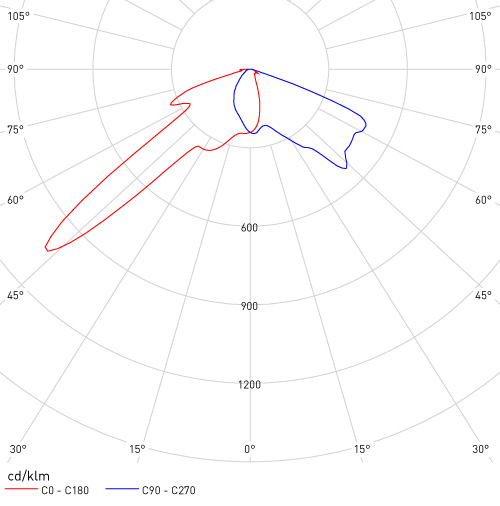

Photometry

Standard Photometries. The SETGA optical department can study additional configurations adapted to each project.

Creators

Jesús Saavedra

Chief Innovation Officer (SETGA)

Jorge Lameiro

Industrial Designer (Pontevedra)

Martín González

Industrial Design Engineer (SETGA)

Do you have a technical question?

Ask us