HERITAGE

HERITAGE

PresentationA NEW SENSORY EXPERIENCE

The desire to bring the design of the old lanterns to their maximum expression was the beginning of a path of new creations of superior quality and innovative ingredients that will stand out the qualities of a unique product.

ORIGIN AND EVOLUTION

The HERITAGE lantern recovers the light essence of the light bodies of yesteryear by applying a complete restyling that transforms it into a timeless, innovative and impressive lantern.

Its formal structure based on curved, simple and elegant lines make it a unique and optimal light complement to integrate into any urban public environment. Without a doubt, a renewal option for an increasingly competitive market.

To make it even more versatile, a smaller lantern is created, the HAARLEM and together they make up this family.

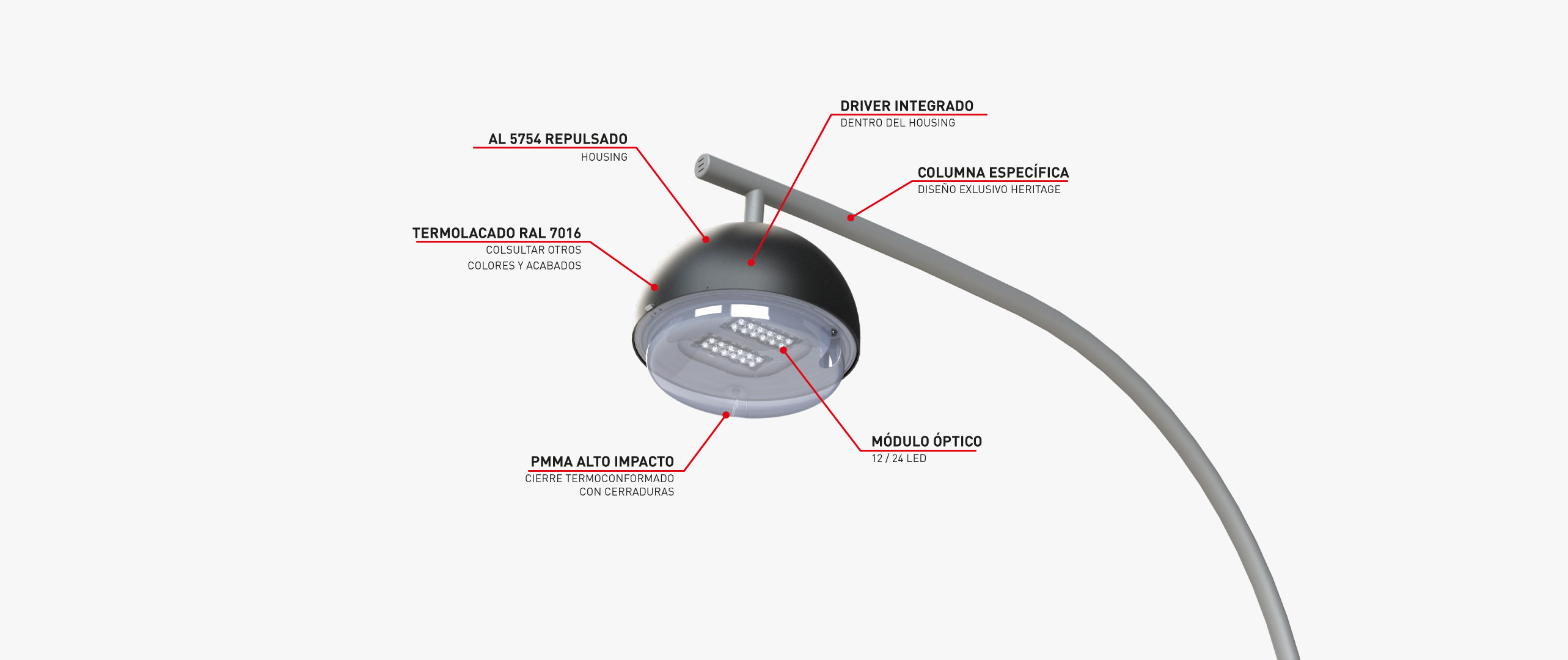

MATERIALS AND STRUCTURE

The hemispherical shape of the Heritage lantern stands out, mainly, for this 5754 repulsed aluminum main body that makes up more than half of the structure. This element is responsible for giving volume and shape to the lantern. Likewise, to store and receive inside the MLD light sources with its integrated dissipation system placed on a chassis adapted to said modules. Its large space allows the possibility of combinations of several MLDs, increasing the number of LEDs.

The bottom surface of this lantern continues with that form of organic curve to give continuity to the whole. This element is a tulip that functions as a closing element and provides a safety area for the light assembly. The material chosen for its manufacture is PMMA treated with an industrial thermoforming process so that the material is modeled according to the matrix mold achieving this curve.

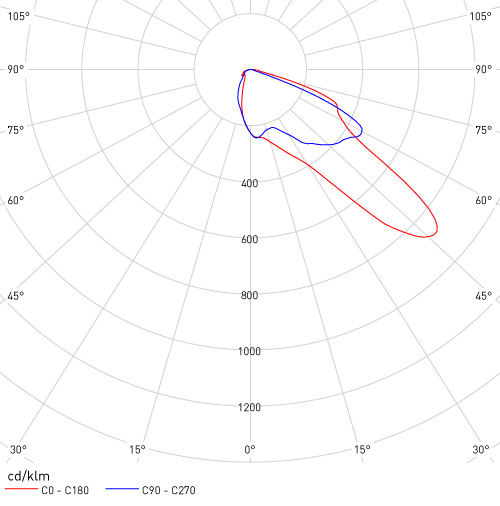

Technical keys

Heritage series are based on the principle of direct thermal dissipation between the LED-PCB and the compact aluminium chassis. The dissipation body comprises a continuous heat pipe of anodized aluminium 6063-T6, which achieves thermal conductivity levels of 200 W/metre Kelvin, compared to 130 W/metre Kelvin of aluminium injection. The low porosity of anodized aluminium plus a thermal pad over the contact surface between the PCB and the dissipation body significantly reduce the diode’s junction temperature

According to the US Energy Agency, relief on the upper surface of

the fixture severely hinders the dissipation process that takes place by convection, becoming a critical element for performance and life.

To overcome this challenge and to enhance the natural self-cleaning process, SETGA has equipped the Heritage lanterns with a uniform upper dome surface, thus preventing dirt accumulation, and the ensuing obstruction and inefficiency of the thermal dissipation system.

Descriptive views

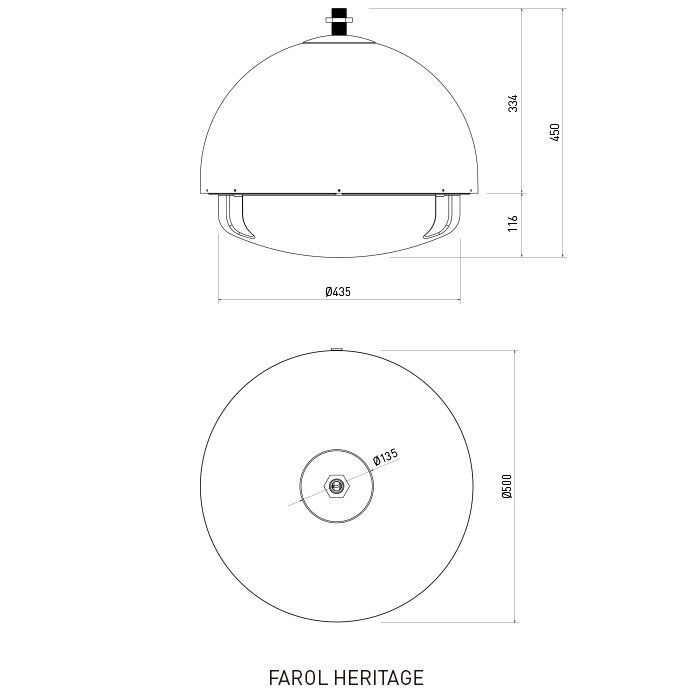

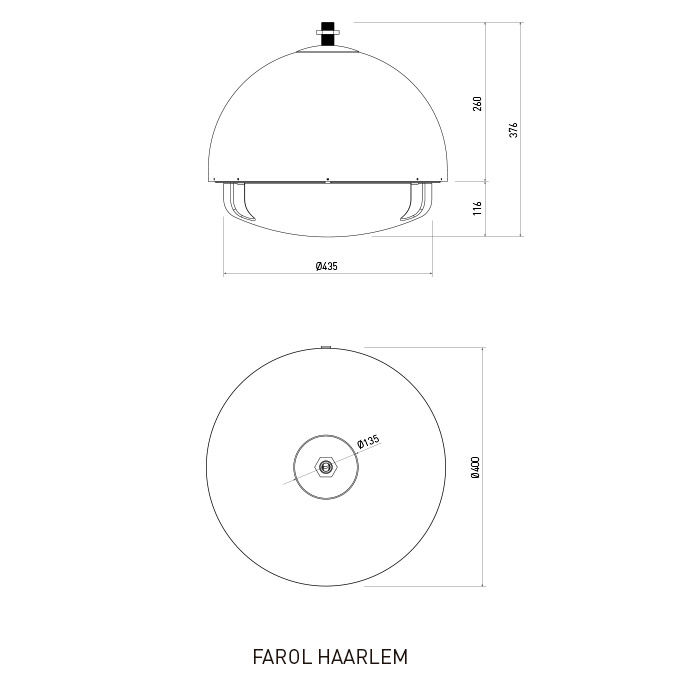

Dimensions and installation

Heritage dimensions remain unchanged, no matter if it is the 12, 24 or 36 LED version. The same happens to Haarlem, its lower diameter version.

The installation of this luminaire is done by threading the socket of the upper part of the luminaire on a support with the same thread, so that the luminaire would be hung from said thread. The position is secured with the built-in locknut. The thread in question would be a Gas Withworth 3/4 ”thread, but other support could be assessed depending on the project and the volume of luminaires.

Iconic projects

HOUTMARKT HAARLEM

Haarlem

Creators

Severiano González

Chief Design Engineer (SETGA)

Do you have a technical question?

Ask us