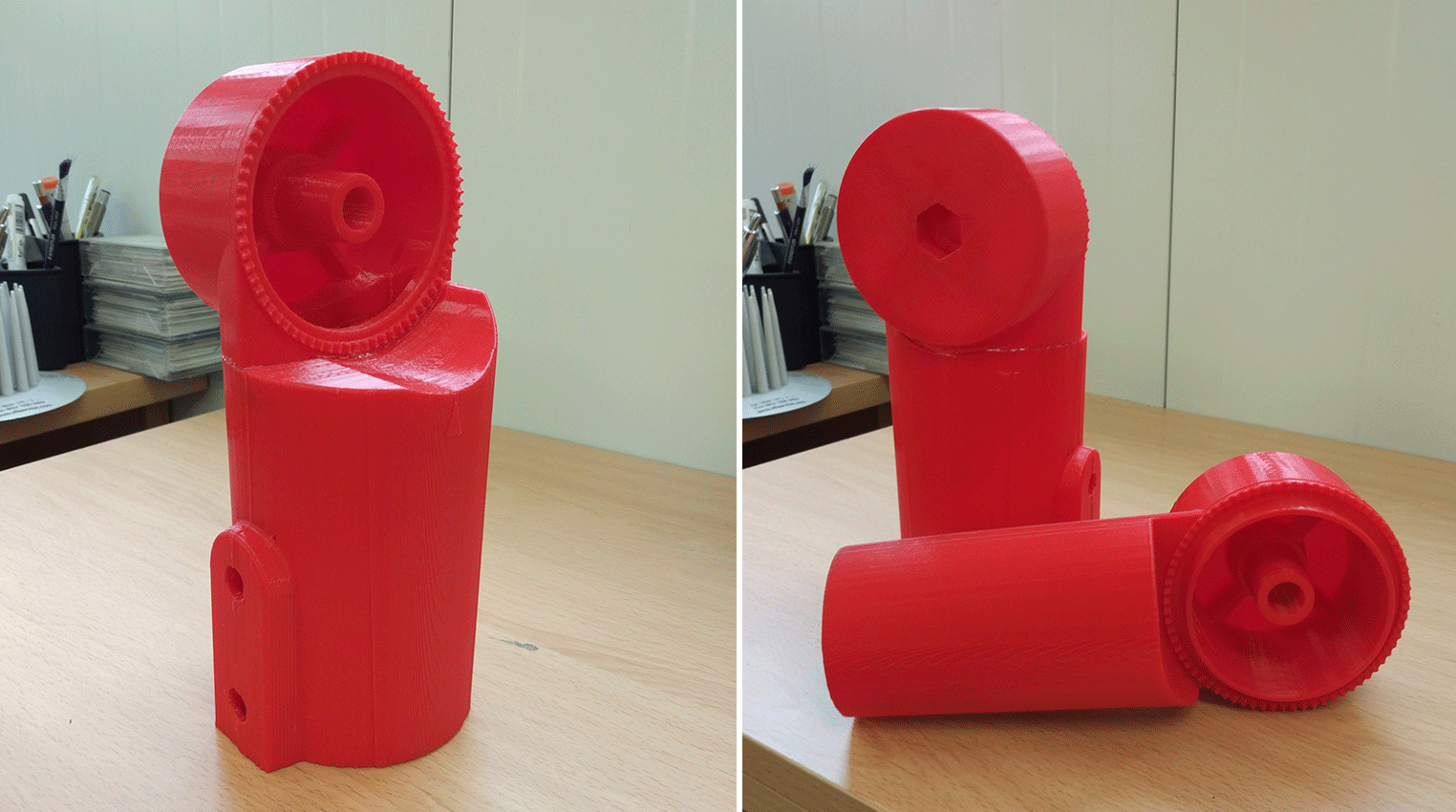

The adaptation of 3D printing technology to the process of developing new LED luminaires allows the creation of pre-series models in the initial design phases, reducing the total average time to market by 60%, from nine to three months.

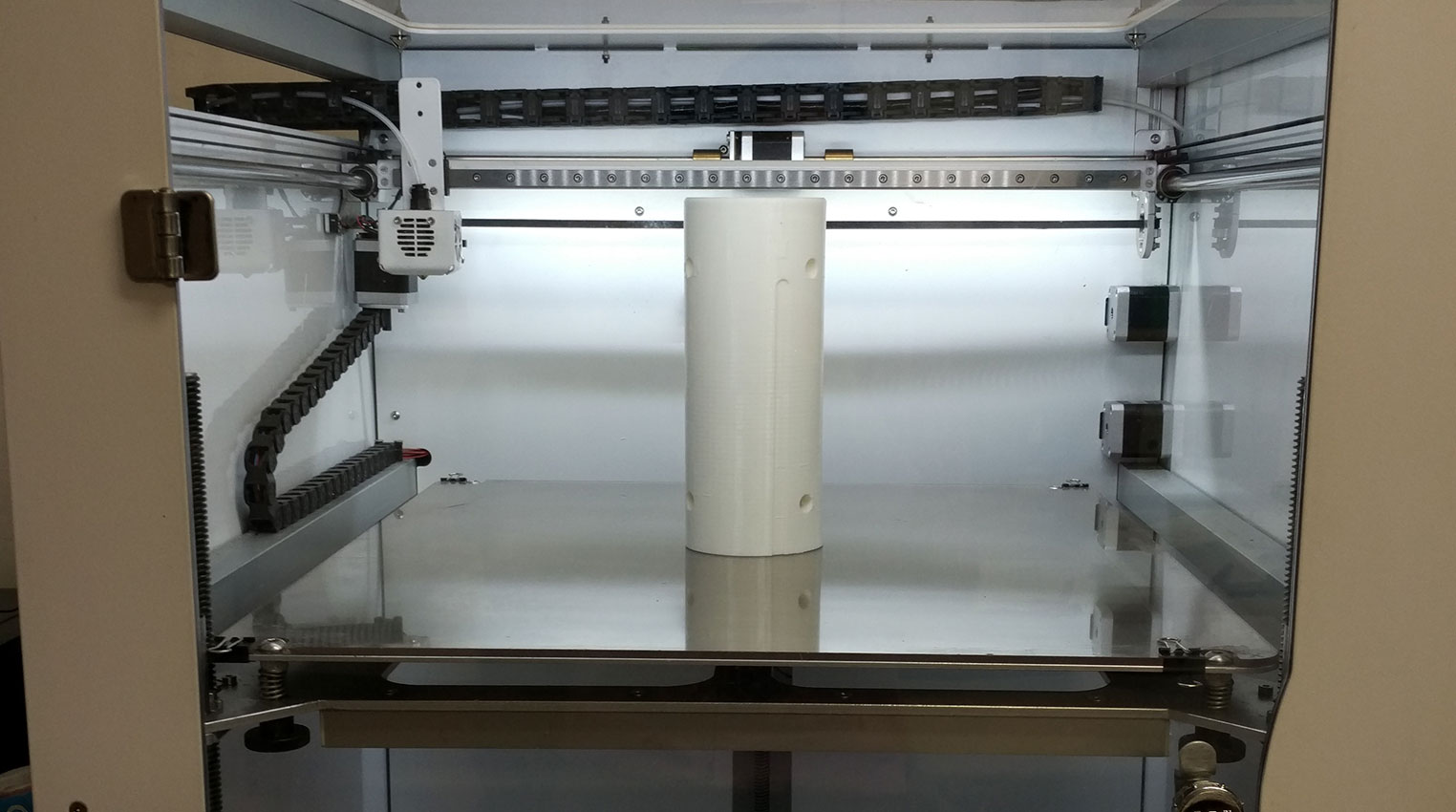

To support this, SETGA has not only invested in the most advanced 3D printing hardware and software systems on the market, it has also adapted the processing of processed materials.

Its application to both co-innovation projects and to the launch of new standard models has managed to redefine the relationship with our customers, providing them with a minimum viable product (MVP) from the outset. On a real scale and in real applications, facilitating the anticipated and continuous rectification required to achieve high levels of excellence and accelerate the speed of innovation.